Description

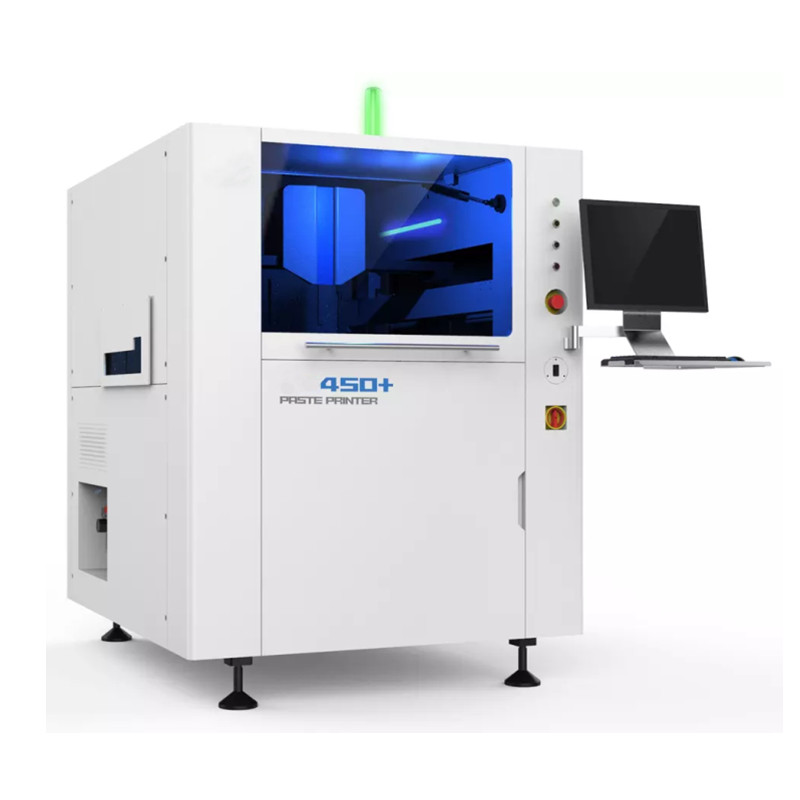

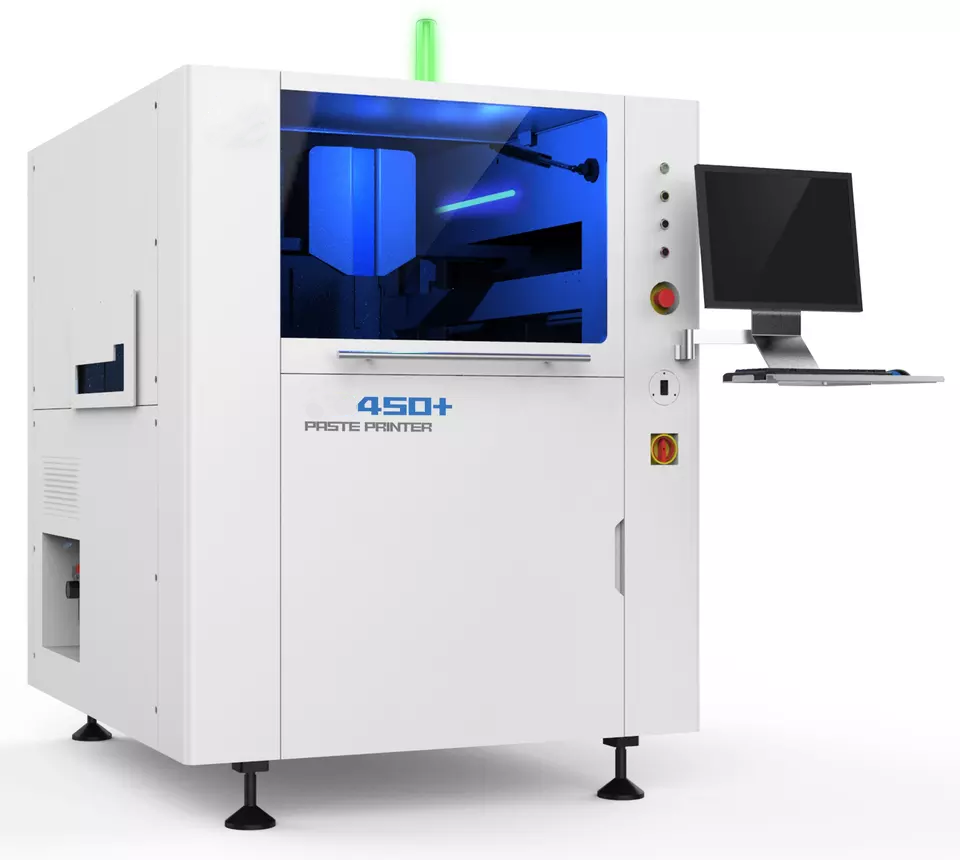

QP450+automatic soldering machine (fully automatic vision solder paste printer )stencil printer machine screen printer machine stencil printer .

The whole machine is fully controlled by servo system.Automatic pressure feedback system.Multifunctional image processing system.

Precise PCB transportation system.Intelligent PCB holding device.Automatic steel mesh positioning module.

Automatic and effective steel mesh cleaning system.User-friendly operation interface.

| PCB Parameters | Ⅰ |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(Y x X) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | Max. PCB ≤1%Diagonal |

| Maximum board weight | 6Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | Left-Right,Right-Left,Left-Left,Right-Right |

| Transfer mode | One stage orbit |

| PCB damping method | Programmable flexible side pressure, (Optional: 1,Bottom integral suction cavity vacuum, 2.Multipoint partial vacuum at the bottom; 3. Edge locking and Substrate clamping) |

| Support method | Magnetic thimble, Equal high block,Vacuum suction cavity; Special workpiece fixture |

| Printing parameters | Ⅱ |

| Printing head | Linear motor type close loop printing head |

| Template frame size | 470mm x 370mm~737 mm x 737 mm |

| Maximum printing area(X x Y) | 450mm x 350mm |

| Squegee type | Steel scraper/Glue scraper (Angel 45°/50°/60° matching the printing process) |

| Squegee length | 220mm~ 500mm |

| Squegee height | 65±1mm |

| Squegee thickness | 0.25mm Diamond-like carbon coating |

| Printing mode | Single or double scraper printing |

| Demoulding length | 0.02 mm – 12 mm |

| Printing speed | 0 ~ 200 mm/s |

| Printing pressure | 0.5kg – 10Kg |

| Printing stroke | ±200 mm (From the center) |

| Field of view | 6.4mm x 4.8mm |

| Platform adjustment range | X.Y:±7.0mm,θ:±2.0° |

| Benchmark point type | Standard shape benchmark point(SMEMA standard), solder pad/openings |

| Camera system | Independent camera,upwards/ downwards imaging vision system |

| Performance parameters | Ⅲ |

| Repetition precision of image calibration | ±15.0micron @6 σ,Cpk ≥ 2.0 |

| Repetition precision of printing | ±20.0micron @6 σ,Cpk ≥ 2.0 |

| Cycle time | <7s |

| Product changeover | <5mins |

| Power supply | AC220V±10%,50/60HZ,15A |

| Air supply | 4~6Kg/cm2, 10.0 Diameter of the tube |

| Gas consumption | About 5L/min |

| Operating system | Windows XP |

| External dimension | 1140mm(L) x 1450mm(W) x 1480mm(H) (Without light,monitor and keyboard) |

| Machine weight | Around 1000Kg |

| Temperature and humidity control module | (optional) |

| Environment temperature | 23±3˚C |

| Relative humidity | 45-70%RH4 |