The advancement of industrial manufacturing technology has accelerated the development of electronic components towards refinement, miniaturization, and complexity. This also poses higher requirements for product factory testing, as even the slightest error can potentially cause fatal harm to the product. Therefore, testing and measurement technology has developed rapidly.

According to Euromonitor International’s data analysis, in the labor-intensive PCB industry, an online AOI device can replace the workload of at least 4-5 people, and the state is stable without rest, which can greatly save labor costs and improve detection efficiency. From this, it can be seen that in the face of the normalization and upgrading of the electronic manufacturing industry, the use of stable and adaptable AOI automatic inspection equipment to replace inspection workers has become an inevitable trend in the industry.

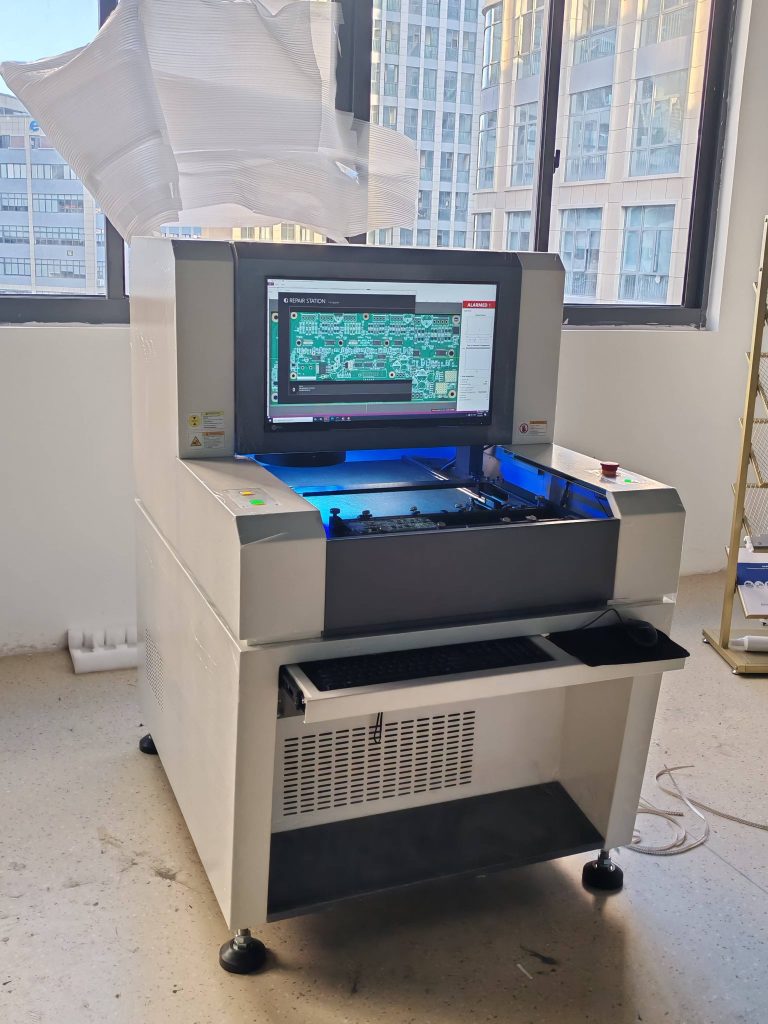

AOI (Automated Optical Inspection) is a core inspection equipment in SMT production lines. Using high-resolution cameras and image algorithms, it automatically captures images of the PCB board after assembly/soldering, compares them to a standard template, and identifies and marks defects.

Functions:

Defect Detection: Accurately identifies SMD placement defects (missing components, wrong components, misalignment, reversed components, tombstoning) and soldering defects (cold solder joints, solder bridges, solder balls, insufficient solder), replacing manual visual inspection and improving inspection efficiency and consistency.

Process Monitoring: Provides real-time feedback on production line process issues (such as pick-and-place machine accuracy drift, abnormal reflow soldering temperature), helping engineers adjust parameters in a timely manner and reduce batch defect rates.

Quality Traceability: Records inspection data and defect information, supporting production quality analysis and traceability, and contributing to continuous process optimization.

Advantages: Non-contact inspection, high speed, high accuracy, suitable for large-scale SMT mass production needs.

About QIHE SMT pick and place machine

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm802b plus,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

-

Wave soldering output conveyor QJ400-BO

-

Benchtop Manual Smt Frameless PCB Solder Paste Stencil Printer Printing Machine

-

SMT Manual Frameless Pcb Solder Paste Stencil Printer

-

SMT frameless steel stencil screen printing table

-

Nitrogen generator, used for selective welding

-

Desktop selection welding QSO-300B

-

Desktop Selective Wave Soldering Machine QH-SHSS341

-

SMT semi-automatic pick and place machine with Dispenser

-

SMT X-Ray Intelligent Item Counting Machine