Smt line cases,including Smt pick&place machine,Stencil Printer, Reflow Oven,pcb handling machines,conveyor,loader,solder paste mixer,

what is smt pick and place machine

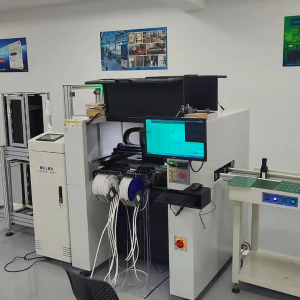

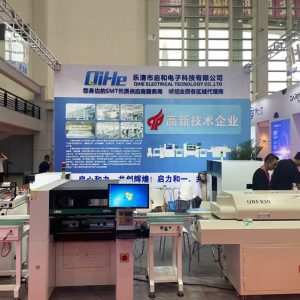

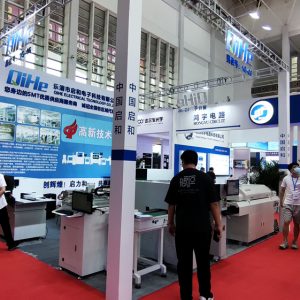

smt pick and place machine use automated processes that make it possible to produce a high number of electronics in a short time. smt pick and place machine are which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Here we sharing smt cases from all around the world .Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

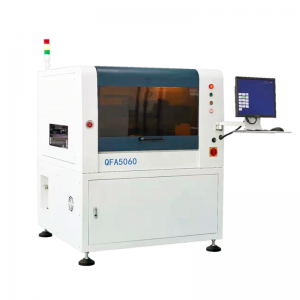

1. Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

2. Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

3. Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.