Smt pick and place machine, Qihe Benchtop Automatic SMT Line

Q4 fully-auto 4heads production line

Mounting size up to 330x330mm. Can handling special-shaped components, BGA, 0201 inch package.Suitable for various types of boards. .The substrate iron plate inside the machine upgrade into thickened marble material.Top speed up to 13000 components per hour (CPH).Newly upgraded the hardware like the highspeed flight camera,the servo driver and motor,the TBI screw rod,and the automatic transfer rail ,Observation windows,monitor & keyboard integrated stand tray.The substrate iron plate inside the machine upgrade into thickened marble material not only increase stability but also improve the accuracy of the working head during high-speed movement .We provide complete economical cost effective solution for fully-automatic SMT line for PCBA assembly . This line include automatic solder paste mixer,fully-automatic Solder Paste printer, PCBA loaders,pcba handling conveyors, Pick and Place machine, Reflow oven, etc.

-

QUL350 pcb up loader machine For Smt Pcb Circuit Board

Read more -

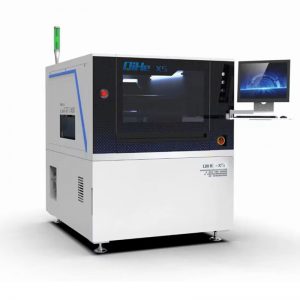

QP5060 automatic solder paste printer stencil printer machine screen printer machine

Read more -

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

Read more -

SMT Inspection Conveyor used for easing, inspection, testing PCBs

Read more -

QRF835 with rail 8 Zones SMT Reflow Oven solder welding

Read more -

QDL350 pcb un loader machine For Smt Pcb Circuit Board

Read more

QL41 LED semi-auto production line

Mounting length up to 1200mm. Suitable for various types of LED strips and boards. speed up to 13000 components per hour (CPH).

We provide complete economical cost effective solution for Semi-automatic SMT line for PCBA assembly for LEDstrip,LED Bulbs,LED Tube Light and other LED boards. This include automatic solder paste mixer,Semi-automatic Solder Paste printer, PCBA loaders,handling conveyors, Pick and Place machine, Reflow oven, etc.

-

QH3502 Automatic Solder Paste Mixer

Read more -

QP1068S Semi Automatic Stencil Printing 1.2meters

Read more -

QUL350 pcb up loader machine For Smt Pcb Circuit Board

Read more -

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

Read more -

QRF1230 12 Zones SMT Reflow Oven solder welding with cabinet

Read more -

QDL350 pcb un loader machine For Smt Pcb Circuit Board

Read more

TVM925S&TVM926S (customized model) fully-auto production line

Mounting size up to 350x350mm. Can handling special-shaped components, BGA, 0201 inch package.Suitable for various types of boards. speed up to 11000 components per hour (CPH).There are two pnp models for you to choose from or also can be combined producing.TVM925S with 50 slots, TVM926S with 63 slots .We provide complete economical cost effective solution for fully-automatic SMT line for PCBA assembly . This line include automatic solder paste mixer,fully-automatic Solder Paste printer, PCBA loaders,pcba handling conveyors, Pick and Place machine, Reflow oven, etc.

-

QUL350 pcb up loader machine For Smt Pcb Circuit Board

Read more -

QP5060 automatic solder paste printer stencil printer machine screen printer machine

Read more -

TVM926S (customized model) SMT pick and place machine 4heads 63slots With Rail Benchtop Pick&Place Machine

Read more -

SMT Inspection Conveyor used for easing, inspection, testing PCBs

Read more -

QRF830 8 Zones SMT Reflow Oven solder welding with cabinet

Read more -

QDL350 pcb un loader machine For Smt Pcb Circuit Board

Read more

What is SMT used for ?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT MACHINE?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe smt can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

1. Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

2. Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

3. Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.