For electronics manufacturing startups, R&D labs and medium-small production workshops, an efficient, stable and cost-effective SMT production line is essential. This solution covers the whole process of solder paste handling, printing, component placement and reflow soldering, enabling high-quality, repeatable PCB assembly.

What Key Equipment Does a Complete SMT Line Include?

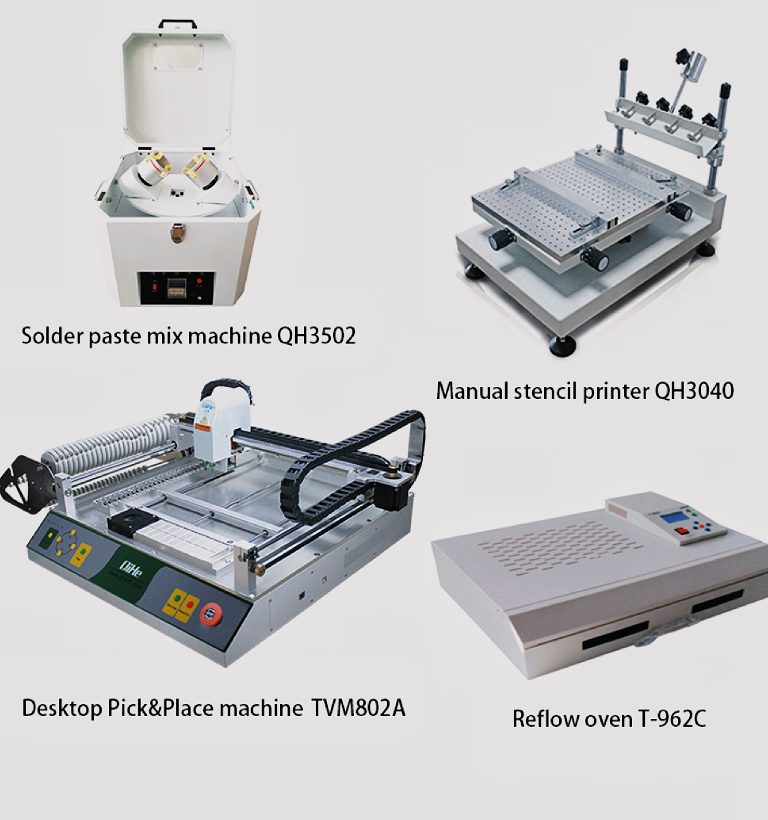

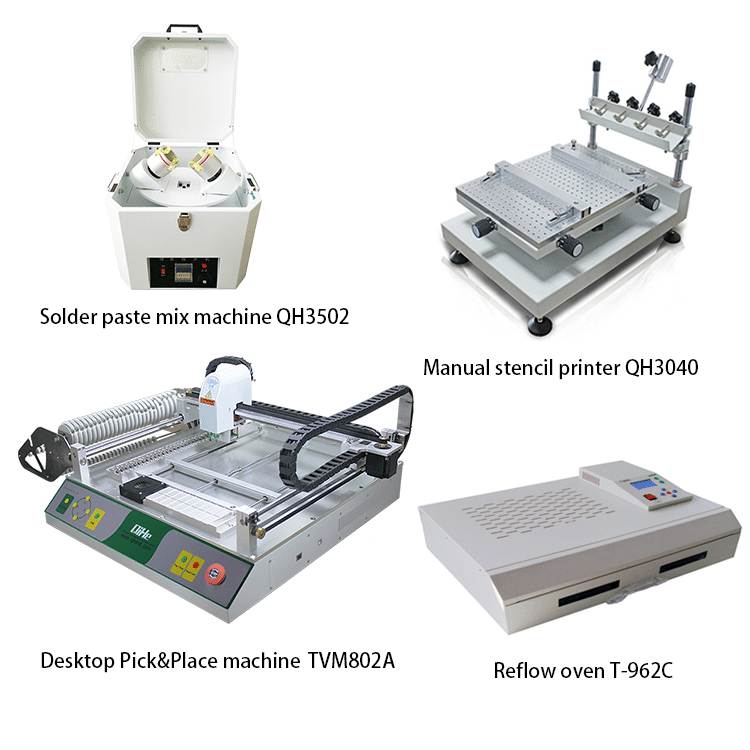

A standard SMT production line typically consists of the following four core stages:

- Solder Paste Mixer (e.g., QH3502)Ensures even mixing of solder paste, prevents sedimentation, and provides stable and reliable solder material for the printing process.

- Manual Stencil Printer (e.g., QH3040)Achieves precise solder paste printing, the first critical step in ensuring soldering quality.

- Desktop Automatic Pick-and-Place Machine (e.g., TVM802A)Places electronic components efficiently and accurately, supports multiple package types, and is ideal for small-batch, high-variety production.

- Reflow Oven (e.g., T-962C)Completes soldering through precise temperature profiling, ensuring components are firmly attached to the PCB.

Why Choose This Production Line Configuration?

· Full Process Coverage: From solder paste preparation to final soldering, equipment is highly compatible and requires no additional adaptation.

· Wide Applicability: Especially suitable for small to medium batch production, R&D prototyping, educational labs, and similar scenarios.

· Easy Operation: Compact equipment design, low learning curve, easy for beginners to master quickly.

· Controlled Cost: Lower investment compared to large fully automated lines, with a shorter return period.

Typical Application Scenarios

· Electronics R&D Labs: For prototype board fabrication and validation.

· Small Batch Order Production: Meets customized, multi-variety order demands.

· Educational and Training Institutions: For electronics process teaching and practical training.

· Startup Production Line Setup: Enables in-house production capability at a lower cost.

We Provide Not Just Equipment, But Solutions

We are committed to providing customizable and scalable SMT production line configurations for global clients. Whether you need a full set of equipment or wish to upgrade a specific stage of your existing line, we can offer professional advice and support tailored to your actual needs.

All equipment supports global shipping and comes with technical guidance, operational training, and after-sales support to ensure a smooth experience from installation to production.

If you are planning an SMT production line or looking to upgrade your existing equipment, feel free to contact us for detailed configuration plans and quotations.

Luna