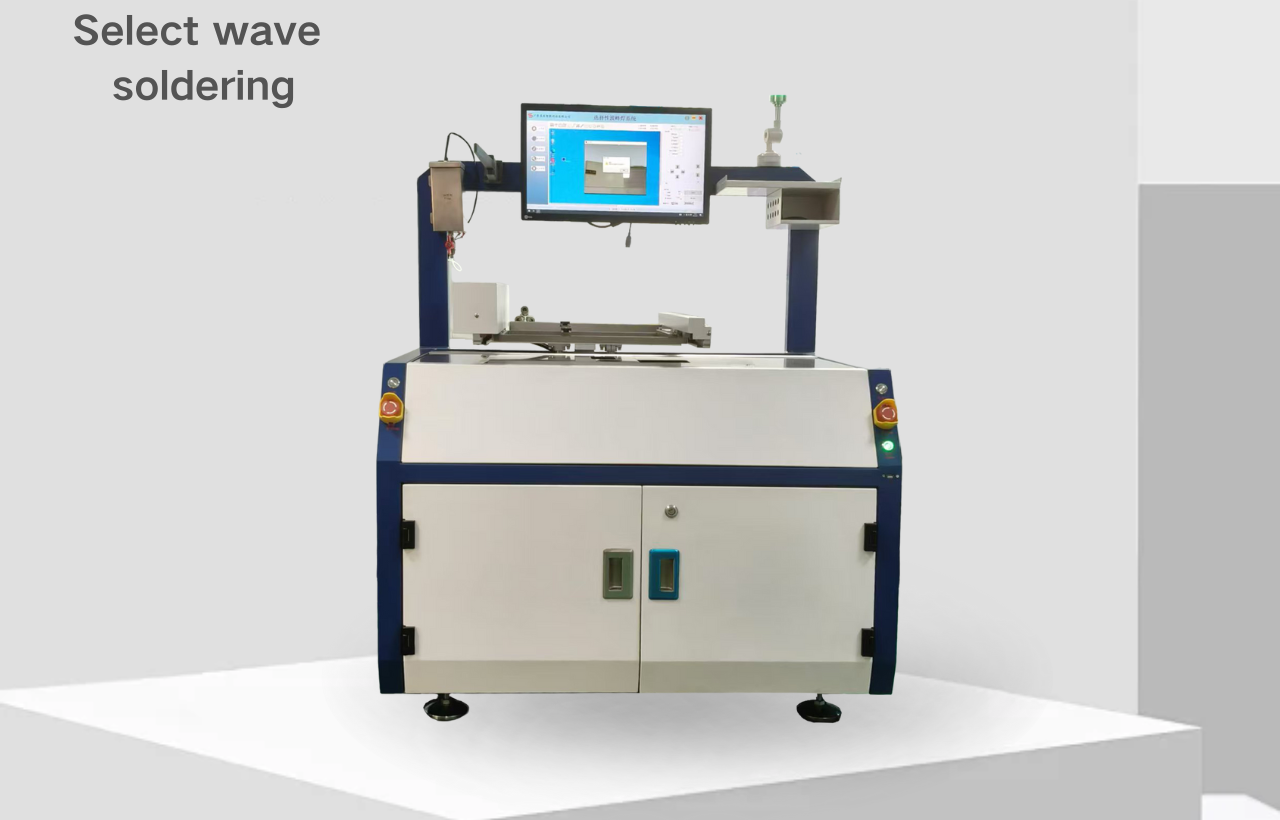

Selective soldering is a localized soldering process used in the post-SMT assembly stage. It is used for precisely soldering solder joints on PCBs that are unsuitable for wave soldering or reflow soldering (such as through-hole components, irregularly shaped components, and areas around heat-sensitive components), offering both flexibility and reliability.

Key Process Steps:

Flux Application: Flux is precisely sprayed onto the target solder joints through a nozzle, wetting only the areas to be soldered.

Preheating: The PCB is locally preheated to activate the flux and prevent thermal shock during soldering.

Dip Soldering / Drag Soldering: The solder nozzle rises, allowing the solder to wet the solder joints; or the PCB moves, dragging the solder joints across the nozzle surface to form full solder joints.

Cooling: The solder joints are cooled naturally or forcibly to ensure a stable crystal structure.

-

Wave soldering output conveyor QJ400-BO

-

Benchtop Manual Smt Frameless PCB Solder Paste Stencil Printer Printing Machine

-

SMT Manual Frameless Pcb Solder Paste Stencil Printer

-

SMT frameless steel stencil screen printing table

-

Nitrogen generator, used for selective welding

-

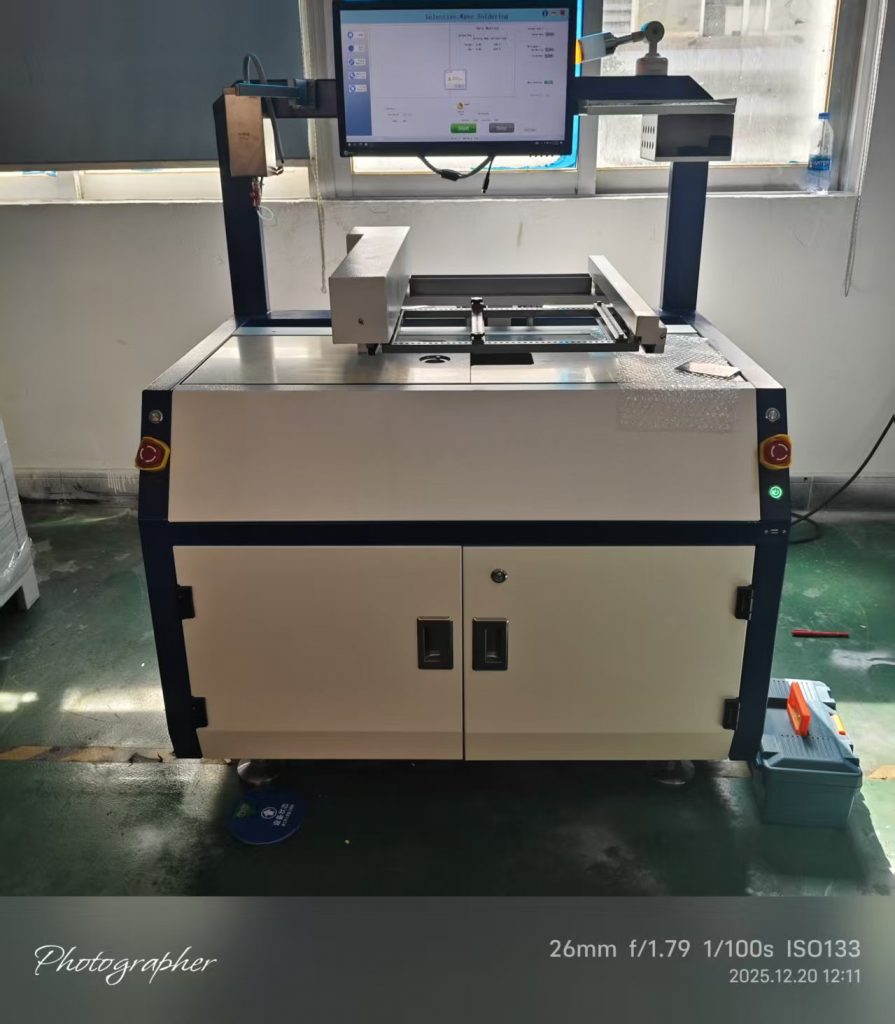

Desktop selection welding QSO-300B

-

Desktop Selective Wave Soldering Machine QH-SHSS341

-

SMT semi-automatic pick and place machine with Dispenser

-

SMT X-Ray Intelligent Item Counting Machine