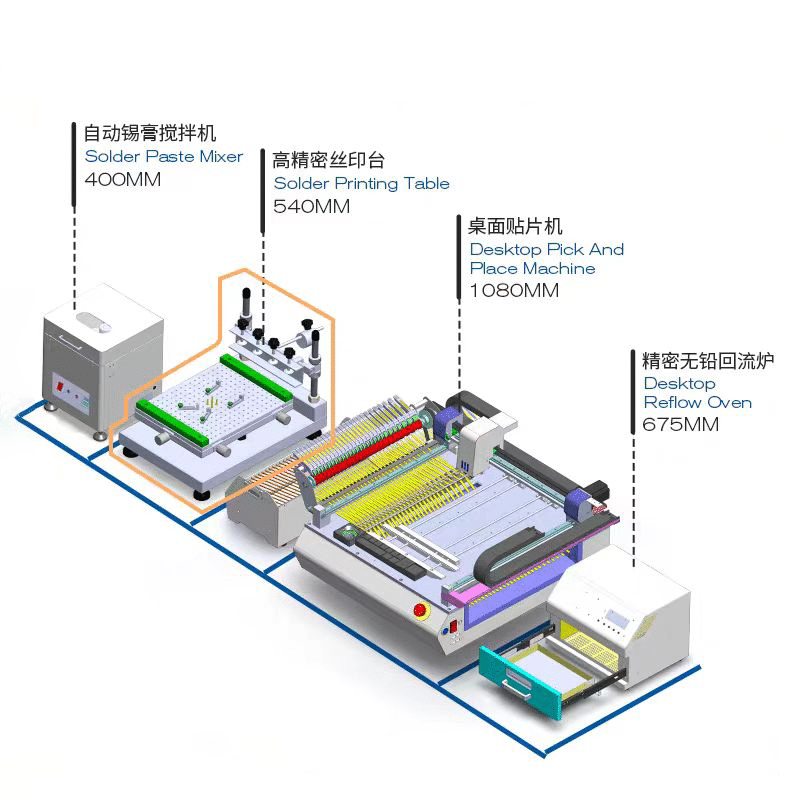

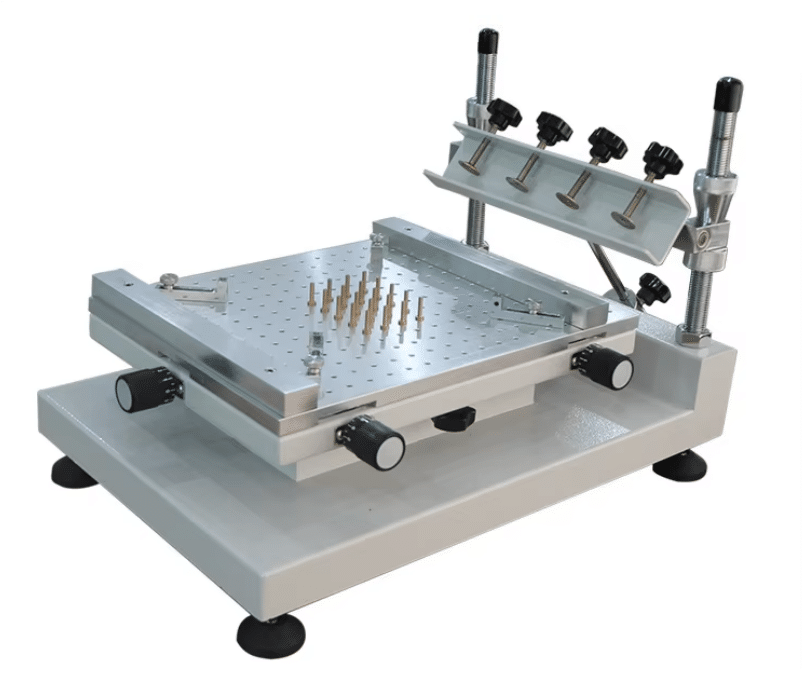

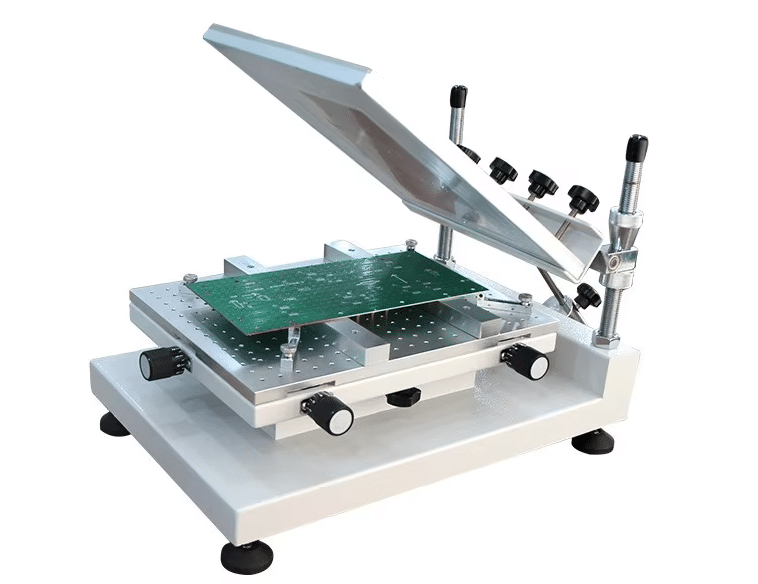

Frame screen pringting machine QH3040:

| Model | QH3040 |

| Workbench size | 300*400 mm |

| Maximum printing size | 300*400 mm |

| Maximum mesh frame size | 370*470 mm |

| Printing speed | Manual control |

| Printing load thickness | 0~80 mm |

| XYZ Axis Adjustment | 10 mm |

| Printing platform height | 220 mm |

| Heavy copy brush accuracy | ±0.01 mm |

| Positioning method | Shape or benchmark hole |

| Overall dimensions | 540*370*380 mm |

| Net weight | 23 kg |

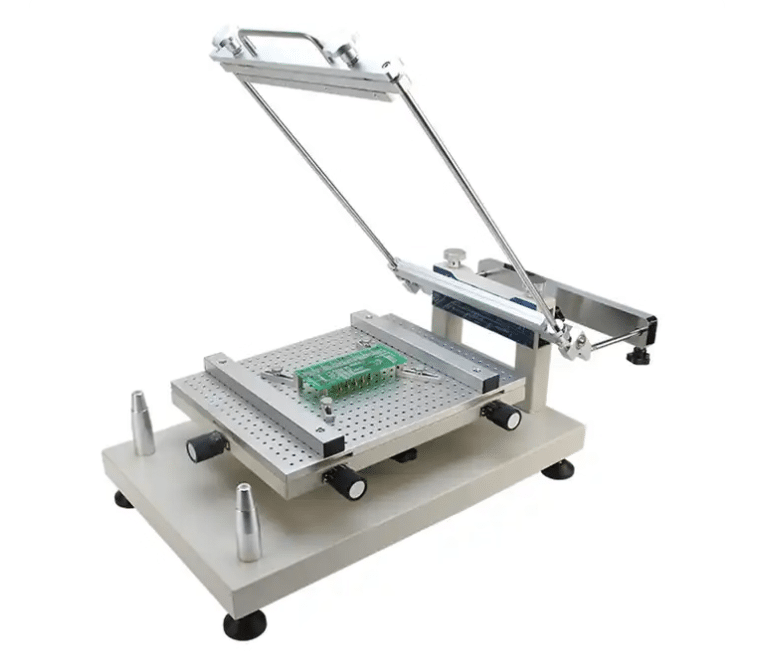

No frame screen pringting machine QH3040UC:

| Technical Data | |

| Model | QH3040UC |

| Workbench Size | 300*400mm |

| Max.Printing Size | 280*380mm |

| Max.Stencil Size | 310*410mm |

| Locating Pin Size | 1.0/1.5/2.0/2.5/3.0mm |

| PCB Thickness | 0-20mm |

| XYZ Axis Adjustment | 15mm |

| Repeatability Precision | ±0.01mm |

| Location Mode | Shape or Benchmark Hole |

| Outline Size | L620*W380*H300mm |

| Weight | 24KG |

Key Differences:

Framed Screen Printing Table: Features a rigid frame, with the screen fixed to the frame. Offers high stability and precision, but is more expensive and less flexible.

Frameless Screen Printing Table: Lacks a fixed frame; the screen requires a tensioning system. Lower cost and easier storage, but precision depends on the tensioning process, and durability is weaker.

Selection Scenarios:

Choose framed:

For large-scale production, automated production lines, and complex PCBs (fine-pitch components), prioritize its stability and precision.

Choose frameless:

For prototyping/small-batch production, limited budgets, and frequent design changes, utilize its low cost and flexibility.

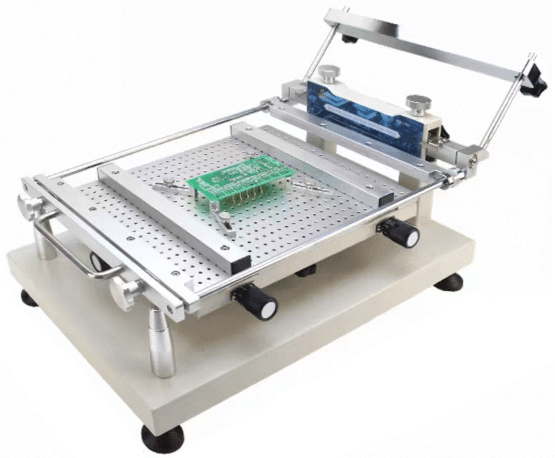

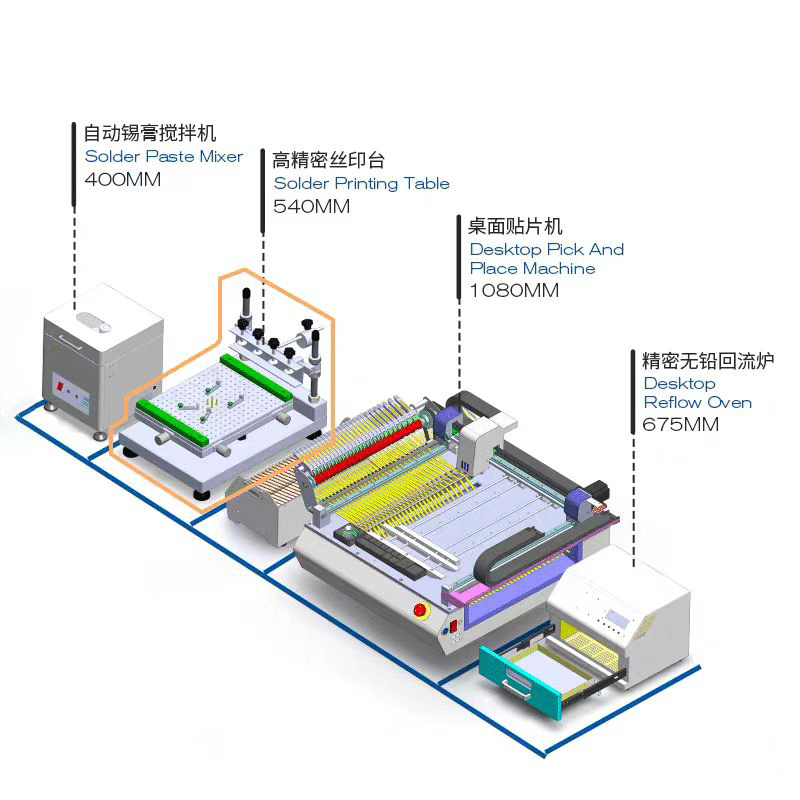

Both are suitable for small-batch printing and customers with limited budgets, and are an important part of the SMT production line.

-

Wave soldering output conveyor QJ400-BO

-

Benchtop Manual Smt Frameless PCB Solder Paste Stencil Printer Printing Machine

-

SMT Manual Frameless Pcb Solder Paste Stencil Printer

-

SMT frameless steel stencil screen printing table

-

Nitrogen generator, used for selective welding

-

Desktop selection welding QSO-300B

-

Desktop Selective Wave Soldering Machine QH-SHSS341

-

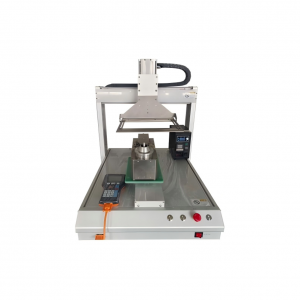

SMT semi-automatic pick and place machine with Dispenser

-

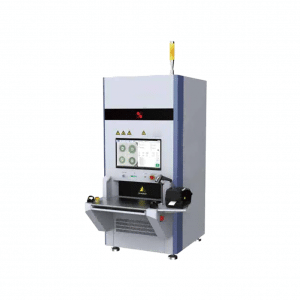

SMT X-Ray Intelligent Item Counting Machine