Tight on budget, short on factory space, or simply looking to streamline your small-batch PCB production? You’re not alone. For startups, R&D teams, and niche electronics makers, a compact PCB production line isn’t just a cost-cutting choice—it’s the key to turning circuit board designs into tangible products fast, without the hassle of outsourcing or scaling unnecessarily.Let’s dive into how a small-scale setup can revolutionize your workflow.

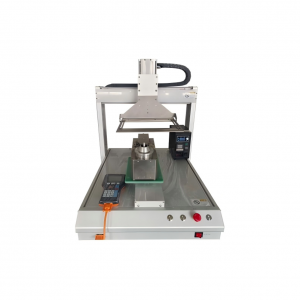

Frameless Screen Printing Machine:

| Technical Data | |

| Model | QH3040UC |

| Workbench Size | 300*400mm |

| Max.Printing Size | 280*380mm |

| Max.Stencil Size | 310*410mm |

| Locating Pin Size | 1.0/1.5/2.0/2.5/3.0mm |

| PCB Thickness | 0-20mm |

| XYZ Axis Adjustment | 15mm |

| Repeatability Precision | ±0.01mm |

| Location Mode | Shape or Benchmark Hole |

| Outline Size | L620*W380*H300mm |

| Weight | 24KG |

Function:

Completes the PCB solder paste printing process, precisely applying solder paste to PCB pads to lay the foundation for subsequent component placement and soldering.

Advantages:

Compact size (L620W380H300mm, only 24KG) saves space; repeat positioning accuracy of 0.01mm ensures precise printing; supports PCBs from 0-20mm thickness for broad adaptability; 15mm adjustable XYZ axes accommodate varying dimensions and positioning requirements (shape/reference hole alignment), making it suitable for small-batch production and prototyping scenarios.

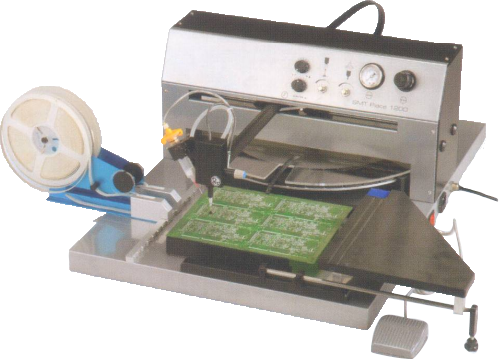

Semiautomatic SMT Pick and Place:

Function:

Rapidly and precisely places SMT components onto pre-solder-pasted PCB locations, bridging the screen printing and reflow soldering processes.

Advantages:

Suited for low-volume, high-variety production and prototyping; accommodates engineering changes; 360° rotating component holder stores 90 types of parts; 16 tape holders accommodate various component sizes; Stable X/Y-axis movement ensures precise placement; SMT-402 includes dispensing functionality for irregularly shaped components; Scalable through parallel operation for low-investment capacity expansion (20-50 pcs/min); Portable design (22 kg).

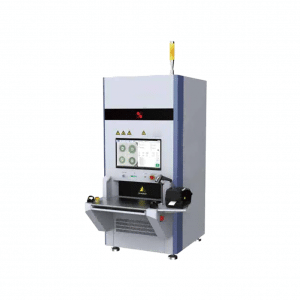

Small reflow soldering

Small reflow soldering:

Function:

Precisely controls heating temperature (0°C-280°C) to melt and solidify solder paste on PCBs, achieving reliable component-to-PCB soldering for finished assembly.

Advantages:

Desktop-sized design (68.4×50.4×22.5cm) for minimal footprint; Maximum soldering area of 400x600mm accommodates small PCBs; Adjustable cycle time from 1-8 minutes optimizes efficiency for small-batch production; Dual voltage compatibility (110V/220V) ensures flexible operation with moderate power consumption (2500W).

-

Wave soldering output conveyor QJ400-BO

-

Benchtop Manual Smt Frameless PCB Solder Paste Stencil Printer Printing Machine

-

SMT Manual Frameless Pcb Solder Paste Stencil Printer

-

SMT frameless steel stencil screen printing table

-

Nitrogen generator, used for selective welding

-

Desktop selection welding QSO-300B

-

Desktop Selective Wave Soldering Machine QH-SHSS341

-

SMT semi-automatic pick and place machine with Dispenser

-

SMT X-Ray Intelligent Item Counting Machine