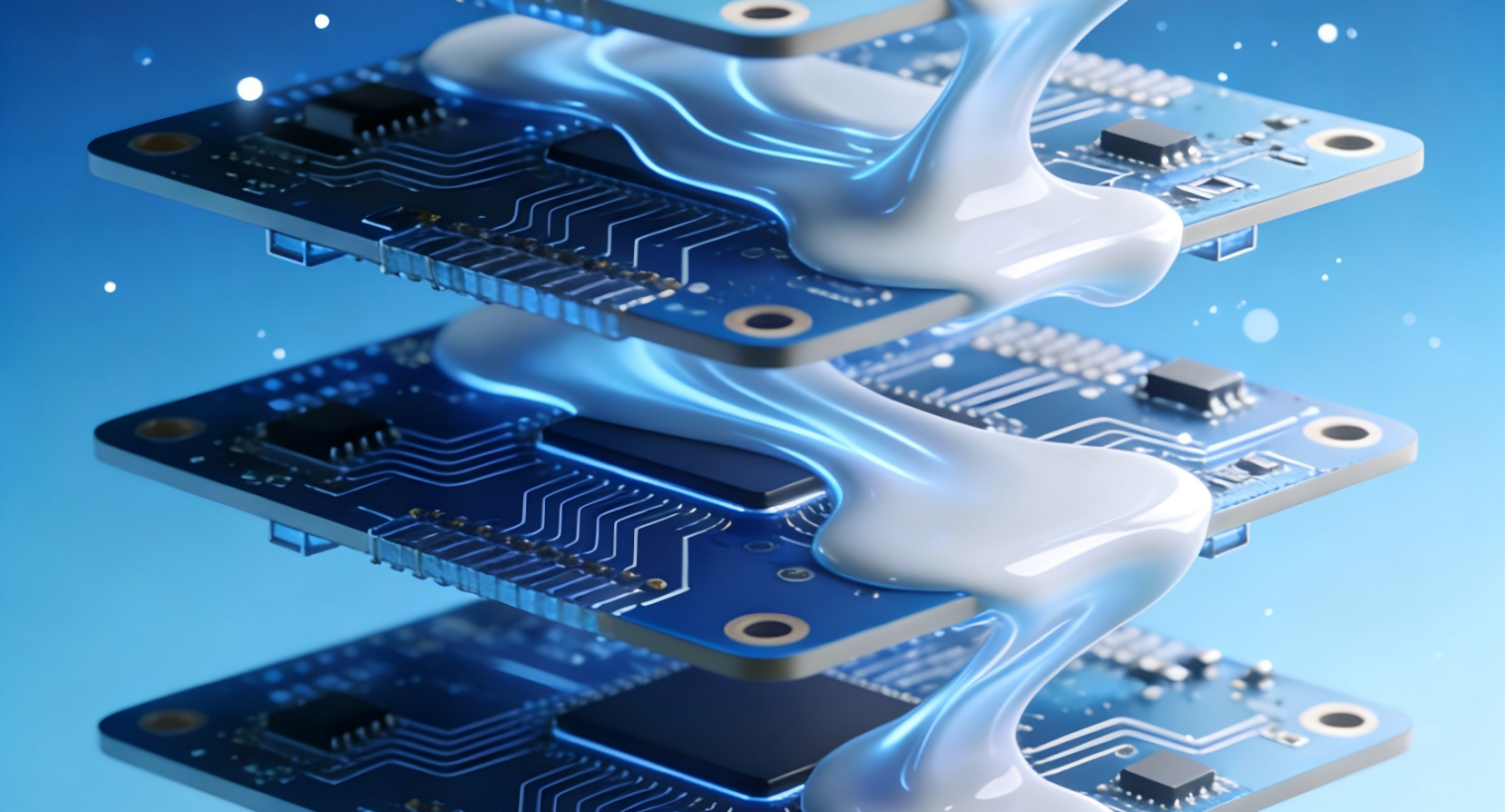

In PCB lamination, “resin flow” (molten prepreg resin overflow under high temp/pressure) often causes impedance deviation, especially impacting high-frequency signal transmission. This article concisely explains its impact paths and control measures.

I. Three Core Paths of Resin Flow Affecting Impedance

1. Uneven Dielectric Thickness: Lower Edge Impedance

More resin flows at board edges, thinning dielectric (20%-30% vs inner board). Dielectric thickness correlates positively with impedance: 10% thickness reduction → 5%-10% impedance drop. Edge impedance is usually 2-5Ω lower, with higher resin content worsening deviation.

2. Local Increase in Dielectric Constant, Aggravating Impedance Reduction

Resin accumulates in areas with concentrated resin flow, making the dielectric constant 0.2-0.5 higher than that in normal areas (e.g., increasing from 3.5 to 4.0). The dielectric constant is negatively correlated with impedance, which, combined with the thinner dielectric layer at the board edges, further reduces impedance.

3. Line Width/Copper Rate Interference: Severe Low-Copper Area Deviation

In low-copper areas (<50%), resin fills line gaps, increasing equivalent line width and reducing dielectric thickness. This dual effect cuts impedance by 3-5Ω, causing poor high-frequency impedance consistency.

II. Resin Flow & Impedance Variations Across Areas

Resin flow and impedance differ by area: high edge flow → 2-5Ω lower impedance (more signal reflection/loss); low inner dense-line flow → target impedance (stable transmission); local high low-copper area flow → 3-5Ω lower impedance (high-frequency distortion).

III. High-Frequency/Mass Production Risks & Controls

High frequency (≥10Gbps): ≥5% impedance deviation worsens eye diagrams and bit error rates. Mass production: uneven flow cuts yield by 10%-20%. Controls include three aspects:

- Material Design: Choose PP with ≤50% resin content; reserve edge flow channels/test strips; increase PP thickness by 5%-10% per 10% copper rate drop;

- Process Control: Adopt stepwise heating/segmented pressure; control flow within 5%-8% of board thickness; use resin dams to limit edge flow;

- Impedance Compensation: Pre-widen edge lines by 5%-10%; simulate flow impact with tools like Si9000 for pre-design parameter correction.