Today, let’s learn how Qihe TVM925S smt pick and place machine doing the housing wafer connectors placement. This time, it is a manual component placement test. Later, it can realize fully automated production by cooperating with the transfer feeder.

SMD wafer connectors should be passed through an oven temperature above 260° for 3-5 seconds. The composition of the patch connector: plastic parts and PIN needles. The materials of plastic parts are generally PA6T and PA9T, which are high temperature resistant materials. SMD connectors are generally used in road cameras, stereo DC fans, smart electronics, air conditioners, high-definition LCD TVs, notebook computers and other fields. Among them, the material of Pin is generally brass, bronze, phosphor bronze, etc. The coating is generally gold-plated (semi-gold) or tin-plated. The coating function of the PIN pin is to resist oxidation, improve electrical conductivity, and increase signal transmission speed.

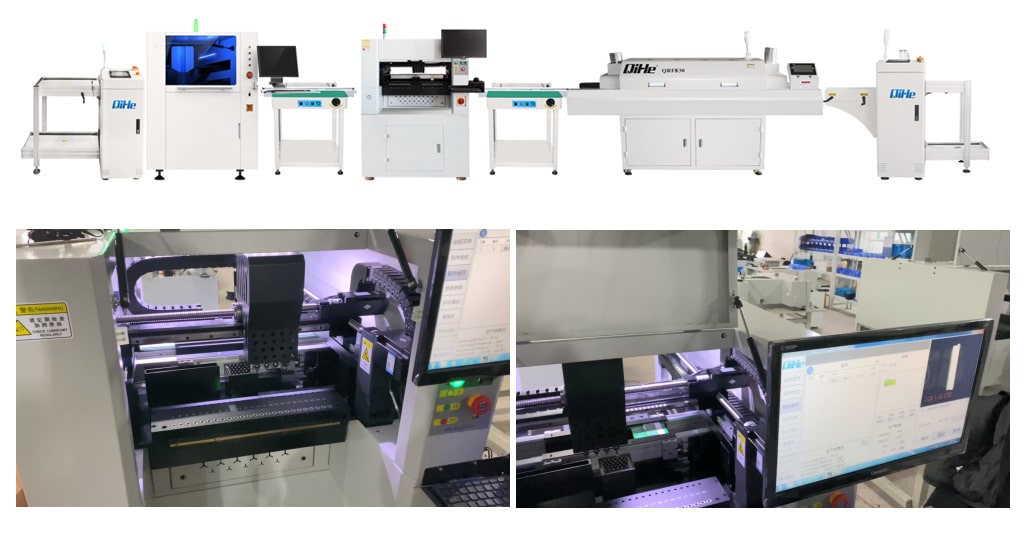

TVM925S smt pick and place machine visual system

Vision system inspecting the housing wafer connector

What is a wafer Connector ?

A wafer connector is in interconnect directly between an unpackaged Integrated Circuit (IC) and some type of a platform (PCB or ceramic substrate). The platform typically delivers power, ground, and signal lines to the IC. The application might be either for testing, or for final packaging.

refer to https://www.paricon-tech.com/wp-content/uploads/2019/10/PariconWaferConnector.pdf

Where can i use wafer housing connectors

The main application fields of the connector are smart home, automobile, communication, computer and peripheral, industrial, military and aerospace….

About QIHE SMT pick and place machine

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm802b plus,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.