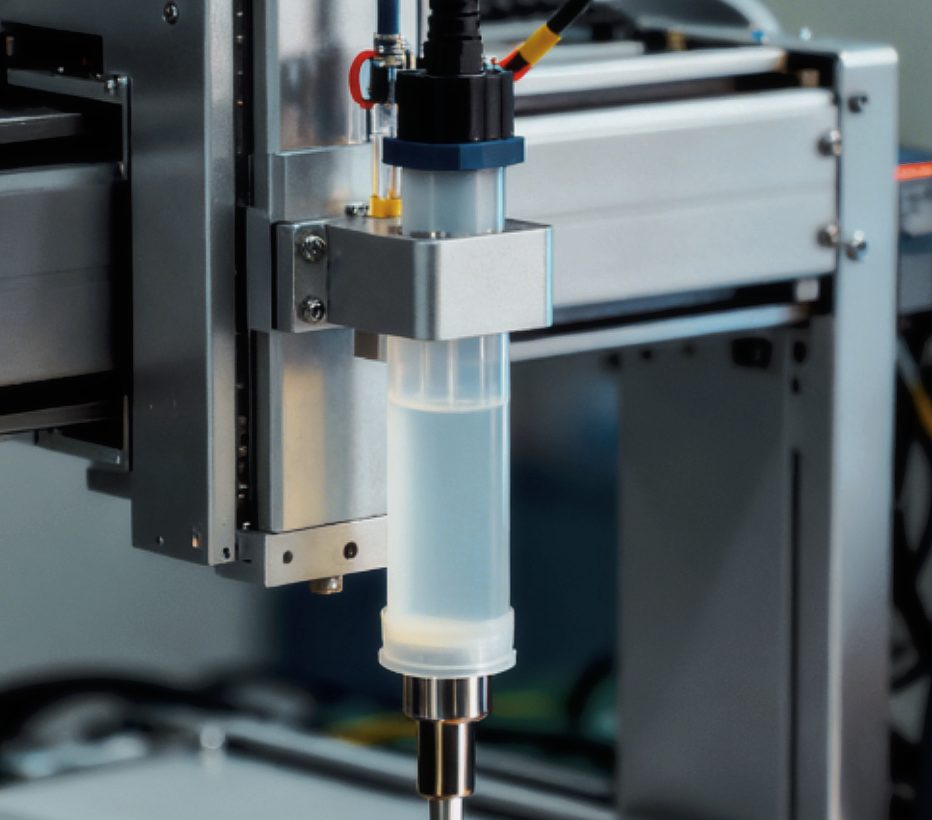

In an era where manufacturing precision is measured down to the micrometer and consistency is key, dispensing machines have become indispensable assets for businesses striving to maintain a competitive edge. These automated fluid application systems are far more than mere “glue dispensers”; they are sophisticated precision tools capable of depositing adhesives, sealants, lubricants, and even conductive pastes with remarkable accuracy. Their influence permeates diverse industries, from consumer electronics to aerospace components, effectively mitigating human error, minimizing material waste, and significantly enhancing production throughput. In this exploration, we will delve into the world of dispensing machines, examining their various types, key advantages, real-world applications, and essential considerations when making an investment.

Types of Dispensing Machines: Finding the Optimal Solution for Your Requirements

Dispensing machines come in a variety of forms, and selecting the appropriate type hinges on factors such as the material being used, the specific application, and the production volume. Here are the most prevalent variants found on today’s manufacturing floors:

- Manual Dispensing Machines: These handheld devices, like syringe dispensers, are particularly well-suited for small-batch production or prototyping. Offering flexibility, they rely on operator proficiency. They present a cost-effective option for startups or low-volume tasks where precision requirements are relatively modest.

- Semi-Automatic Dispensers: Combining manual control with mechanical assistance, these machines alleviate operator fatigue while enhancing consistency. They often feature foot pedals for hands-free operation and adjustable pressure settings to accommodate different fluids.

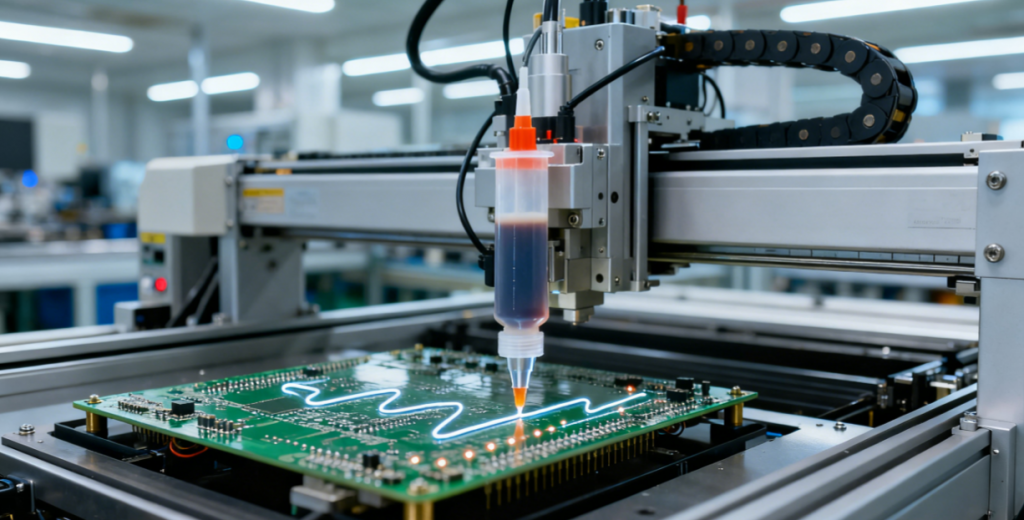

- Fully Automatic Dispensers: These are the workhorses of high-volume production. Integrated with robotics, vision sensors, and CNC controls, they deliver pinpoint accuracy. Capable of handling complex patterns, processing multiple workpieces simultaneously, and operating 24/7, they are ideal for electronics assembly lines and automotive part manufacturing.

- Specialized Dispensers: Tailored to niche applications, such as UV-curable adhesive dispensing (equipped with built-in UV lamps) or dual-component dispensing (for precisely mixing resins and hardeners in specific ratios).

Key Benefits of Investing in a High-Quality Dispensing Machine

The return on investment (ROI) of a dispensing machine extends well beyond mere efficiency gains; it has a direct impact on product quality and bottom-line profitability:

- Unrivaled Precision: Modern dispensers can deposit fluids in volumes as minuscule as 0.001ml, ensuring consistent application even on micro-components like semiconductor chips or medical devices. This eliminates defects caused by over-dispensing or uneven bonding.

- Material Conservation: By precisely controlling fluid flow, dispensers can reduce waste by up to 30% compared to manual application methods. For costly materials, such as conductive inks or medical-grade adhesives, this translates into substantial cost savings.

- Enhanced Productivity: Automated systems operate at speeds far exceeding human capabilities; some can complete over 1,000 dispensing cycles per hour. This shortens production lead times and enables businesses to scale up output without a proportional increase in labor.

- Batch-to-Batch Consistency: Unlike human operators, machines deliver identical results every time, ensuring compliance with industry standards (such as ISO certifications) and reducing the likelihood of product recalls.

- Improved Worker Safety: Dispensing machines minimize operator exposure to hazardous fluids, such as toxic adhesives or corrosive sealants, thereby enhancing workplace safety and reducing liability risks.

Real-World Applications: Where Dispensing Machines Excel

Dispensing machines are omnipresent in manufacturing, and their versatility often surprises even seasoned industry professionals:

- Electronics: From bonding circuit boards and encapsulating microchips to applying thermal paste on CPUs, dispensers play a crucial role in ensuring the reliability of smartphones, laptops, and IoT devices. Vision-guided systems can even adapt to slight variations in component placement.

- Automotive: Employed for sealing windshields, bonding interior panels, lubricating mechanical parts, and applying adhesive to battery packs in electric vehicles. Their ability to handle high-viscosity materials, such as structural adhesives, makes them indispensable in automotive assembly.

- Medical Devices: Vital for the assembly of syringes, catheters, and implantable devices, where precision and biocompatibility are non-negotiable. Dispensers deposit medical-grade adhesives in sterile environments, adhering strictly to FDA guidelines.

- Aerospace: Used to bond lightweight materials, such as carbon fiber, in aircraft components, apply anti-corrosion sealants, and dispense thermal protection coatings. The high reliability of automatic systems is essential for meeting aerospace safety standards.

- Consumer Goods: From sealing toothpaste tubes and bonding plastic toys to applying labels on bottles, dispensers enhance efficiency in mass-produced items while maintaining product quality.

How to Select the Right Dispensing Machine for Your Business

Choosing a dispenser requires a meticulous evaluation of your specific needs. Here is a step-by-step guide:

- Define Your Application: Identify the type of fluid (adhesive, sealant, lubricant), its viscosity (ranging from thin liquids to thick pastes), and the required dispensing volume. For instance, high-viscosity materials may necessitate a piston-driven dispenser, while thin fluids are better suited to air-powered systems.

- Assess Precision Requirements: Determine the tolerances you need (e.g., ±0.01mm for microelectronics versus ±0.1mm for general assembly). Vision-guided systems are a worthwhile investment when working with small or irregularly shaped components.

- Evaluate Production Volume: Small-batch operations can benefit from cost savings with manual or semi-automatic systems, whereas high-volume production demands fully automatic dispensers with integration capabilities (such as compatibility with conveyor belts or robotic arms).

- Consider Material Compatibility: Ensure that the machine’s components (including needles, hoses, and reservoirs) are resistant to the fluid in use. For example, corrosive fluids may require stainless steel or Teflon parts.

- Seek User-Friendly Features: Intuitive touchscreen controls, ease of maintenance, and remote monitoring (via IoT) can reduce downtime and training costs. Some modern dispensers even offer predictive maintenance alerts to prevent breakdowns.

The Future of Dispensing Machines: Trends to Anticipate

As the manufacturing landscape continues to evolve, dispensing machines are keeping pace with cutting-edge technologies:

- IoT Integration: Smart dispensers can connect to factory management systems, providing real-time data on performance, material usage, and maintenance requirements. This enables predictive maintenance and data-driven process optimization.

- AI-Powered Vision Systems: Advanced AI algorithms empower dispensers to adapt in real-time to dynamic conditions, such as component misalignment or changes in material viscosity, reducing setup time and enhancing accuracy.

- Sustainability Focus: Manufacturers are developing dispensers that minimize energy consumption and incorporate eco-friendly materials in their construction. Additionally, precision dispensing reduces material waste, aligning with global sustainability objectives.

- Miniaturization: As components become smaller, particularly in wearable technology and micro-medical devices, dispensers are being engineered to handle even tinier volumes and more intricate patterns.

Conclusion: Investing in Precision for Sustained Success

Dispensing machines are no longer a luxury; they are a necessity for businesses aiming to thrive in today’s highly competitive manufacturing environment. Whether you operate a small startup or a large enterprise, the right dispenser can elevate product quality, cut costs, and boost productivity, all while positioning your business for future growth. By understanding your application requirements, carefully evaluating key features, and staying abreast of industry trends, you can select a dispensing machine that offers enduring value.

Ready to elevate your production line to new heights? Begin by consulting with a reputable dispensing machine manufacturer to assess your specific needs. This investment is bound to yield dividends in the form of satisfied customers, fewer defects, and a healthier bottom line.