Description

Functions

Precise local soldering: Selective tin spraying soldering is performed for specific solder joints on PCBs, such as plug-in components and irregular components, to avoid sensitive components and reduce thermal damage.

Suitable for small batch production: The desktop design is flexible and portable, suitable for research and development sampling, small batch and multi variety SMT production line soldering, and reduces the cost of changing lines.

Improving welding quality: Compared to manual welding, the amount of solder can be controlled, the consistency of solder joints is high, reducing virtual soldering and continuous soldering defects, and ensuring product reliability.

| Specifications | Parameter |

| Overall Dimensions | 1100L*790W*1500H(mm) |

| Machine frame | Steel structure+baking paint |

| Machine appearance | Open-type |

| Board-taking and -placing method | Manual taking and placing |

| Operating height | 900±20mm |

| Weight | Approx.280KG |

| Power supply | 1φ 220V 50/60HZ |

| Total power | 3KW |

| Welding real-time monitoring | Standard configuration |

| Programming methods | Picture programming,Gerber document,visual teaching programming, etc. |

| PCB parameter | |

| PCB size | Min:30(L)*30(W);Max:350(L)*250(W)(mm) |

| Top component height | Max280mm |

| Bottom component height | Max30mm |

| PCB Weight | Max5Kg |

| PCB Process Edge | >3mm |

| Selective spray system | |

| Spray movement mode | PCB movement in XYZ axis |

| Spray flux volume | 1L |

| Spray flux add mode | Manual |

| Spray nozzle type | Needle |

| Spray cycle time | 1 Sec/soldered dot(The minimum spray time can be set to 0.1 seconds) |

| Spray movement precision | 0.05mm |

| Spray flow control | Pressure gage +flow valve |

| Spray travel speed | 0-400 mm per second adjustable |

| Selective Soldering System | |

| Welding movement mode | PCB movement in XYZ axis |

| Movement mode | Servo motor +linear rail |

| Solder feeding mode | Manual |

| Solder capacity | 15KG |

| Solder melting time | 45min |

| Solder power | 1.2KW |

| Solder nozzle size | Standard with 5 solder tips(3-64-86-108-1210-14) |

| Solder cycle time | 1~6 Sec/soldered dot |

| Temperature control mode | PID+SSR |

| Temperature setting range | Max350℃ |

| Temperature accuracy | ±2℃ |

| Waver height | Max 0-8mm |

| Welding precision | ±0.1mm |

| welding moving speed | 0-4000mm adjustable |

| Solder dross | 0.2Kg/8H(Not N2 protection);0.01Kg/8H(N2 protection) |

| N2 protection system | |

| N2 protection mode | Nozzle and solder pot |

| N2 consumption | 1.5M³/h(Nitrogen concentration>99.999%) |

| N2 flow control | Glass rotor flowmeter |

| Exhaust system | |

| Top cover exhaust | Customer supply |

| Exhaust quantity | 1 PCS |

| Exhaust volume | About 5m³/h(Provided by the customer with an external exhaust channel) |

| Control system | |

| Control mode | PC+motion control card |

| PCB Process parameter | Setting,save,open in the PC screen |

| Other | PCB counting,message,alarm can be read in the PC |

| Option | |

| Electromagnetic pump tin furnace | |

| Flux injection valve | |

| 500°high temperature tin furnace | |

| Peak height detection | |

| 2cubic nitrogen generator | |

| Common Wear &Tear Parts | |

| Welding nozzle,nozzle cleaning fluid,high-temperature bearing | |

-

Wave soldering output conveyor QJ400-BO

-

Benchtop Manual Smt Frameless PCB Solder Paste Stencil Printer Printing Machine

-

SMT Manual Frameless Pcb Solder Paste Stencil Printer

-

SMT frameless steel stencil screen printing table

-

Nitrogen generator, used for selective welding

-

Desktop selection welding QSO-300B

-

Desktop Selective Wave Soldering Machine QH-SHSS341

-

SMT semi-automatic pick and place machine with Dispenser

-

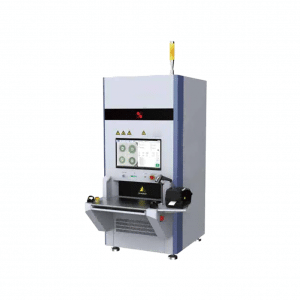

SMT X-Ray Intelligent Item Counting Machine