Description

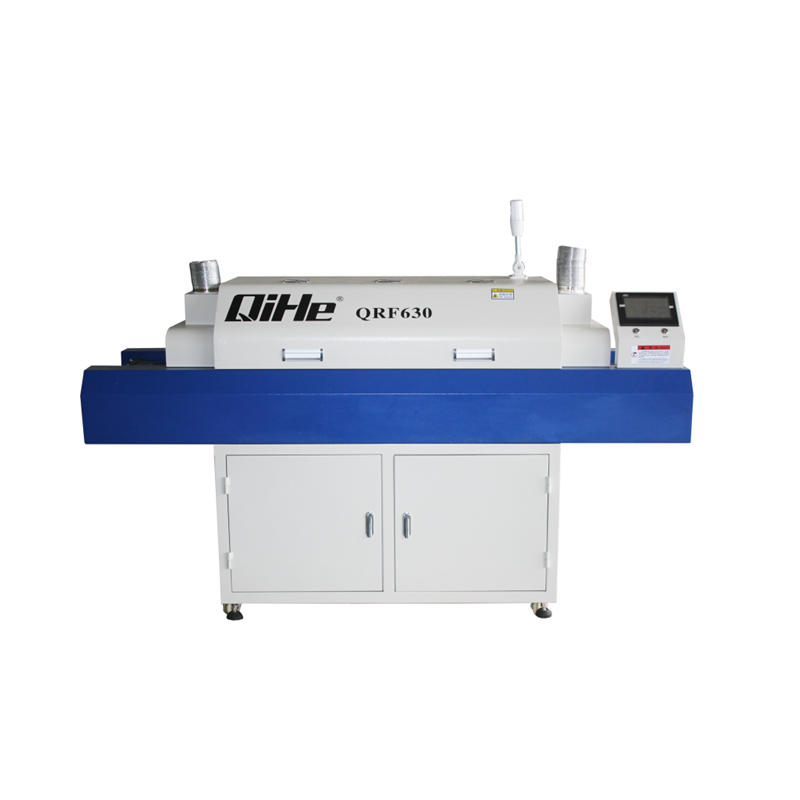

QiHe QRF630 infrared benchtop reflow oven 6 zones ,Length of heating zone 1060mm ,power 3kw,

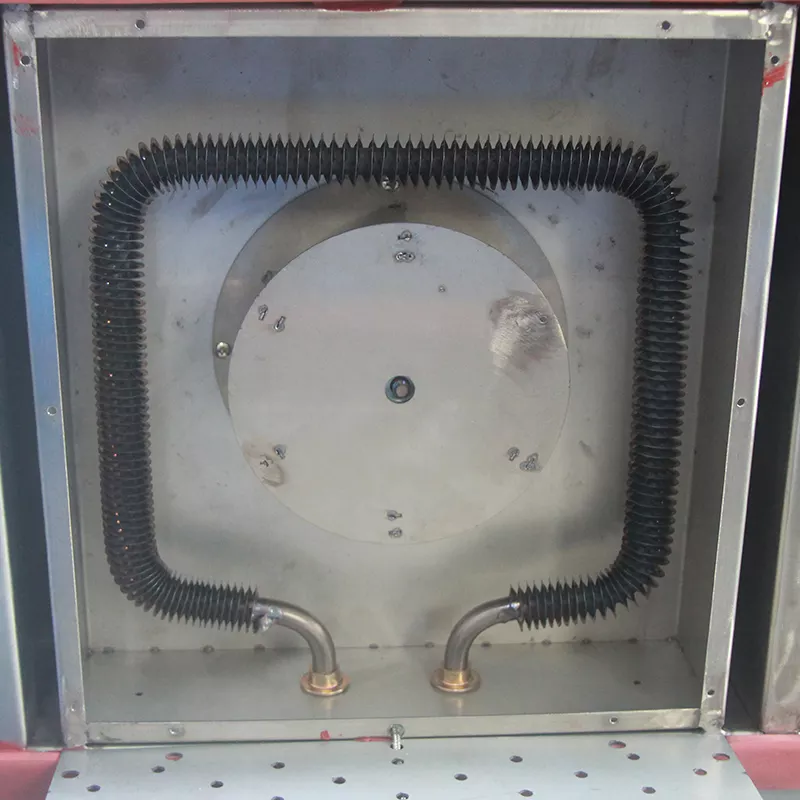

The QRF630 the PID temperature control system and rapid infrared heating technology controlling, so the temperature is being kept very accurate and evenly distributed. The whole soldering process can be completed automatically and it is very easy to use. It is suitable for the board has chips and output is larger or the welding quality requirements are better.Designed with Multi-temperature curve choose.Four zones special temperature control mode more stable and precise.High quality thermocouple porcelain bead protect.Full-color HMI human-computer interface(touch screen).Super anti-temperature fan.Liner hearth use industrial grade anti high temperature and corrosion panel paint.PID microcomputer global temperature control system. High efficiency and energy saving finned heating tube.High temperature fan.Built in analog governor.

| Model | QRF630 |

| Heat zone numbers | 6 zones(Up3, Down3) |

| Heat method | Hot wind |

| Cooling zone numbers | Two natural air cooling |

| Length of heating zone | 1060mm |

| Width of net belt | 300mm |

| PCB size | 280mm |

| Height of net belt | 900±20mm |

| Transport speed of net belt | 160~1350mm/min(Analog quantity adjusting) |

| Transport direction of net belt | Left to right( right to left) |

| Starting power | 9KW |

| Working power | 3KW |

| Input supply power | Three-phase five-wire 380±10% 50HZ |

| Heat up time | About 20 mins |

| Time of passing through the machine | 3.5 to 5.5 mins |

| Range of temperature control | Indoor temperature to 400 degrees |

| Method of temperature control | PID close cycle control |

| Net weight | 215kg |

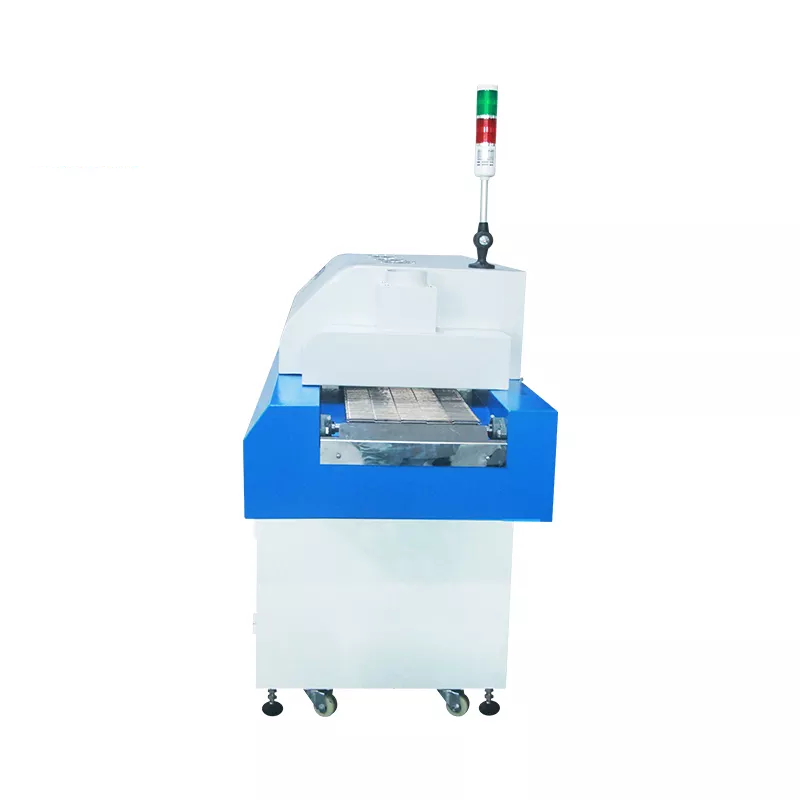

| Outline size | 2100x680x1200mm |