Description

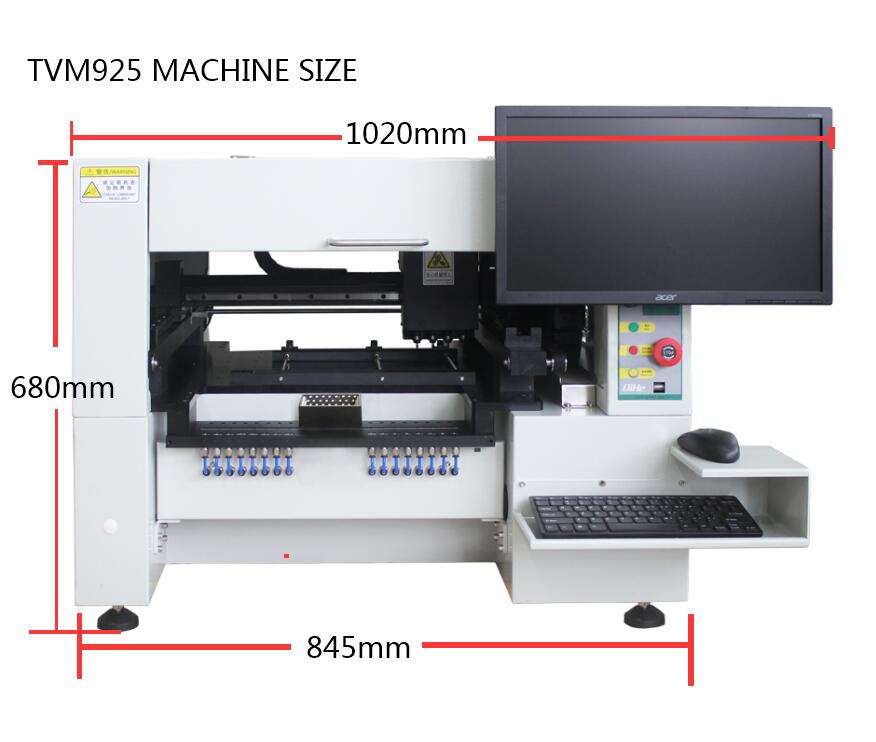

The TVM925 smt pick and place machine is designed with 4 heads,38 slots.

TVM925 the XY axis is driven by closed-loop motors, with good control performance and no step loss during movement.

Support component library function,manage various electronic components efficiently. It support 0402、SOP、QFN144、BGA and so on.

TVM925 supports both pneu-matic and electrical feeders, connect up to 38pcs of feeders. Support vibration feeders.

| Model | TVM925 | |

| Applicable PCB | 20x20mm~310x360mm | |

| XY moving range | 375mmx620mm | |

| Z moving range | 16mm | |

| Placement head quantity | 4 | |

| Mounting capability | 9000pcs/h Without vision | |

| 7000pcs/h With vision | ||

| Mounting accuracy | 0.025mm | |

| Applicable components | 0402.0603.0805.sop8.…QFN | |

| Components supply | Tape reel.bulk package(IC)tubes | |

| Motor control scheme | Closed -loop stepping servo system | |

| Tape width | 8mm.12mm.16mm.24mm | |

| Feeders loading ability | 38(YAMAHA Feeder is available) | |

| Machine dimension | L845xW865xH650mm | |

| Visual camera | 1 PCB inspection camera ,1 Flying camera | |

| Visual camera(down) | Automatic identify the mark point | |

| Visual camera(up) | Automatic adjust the offset | |

| Vacuum pump quality | External air pump | |

| Power supply | AC220V/AC110V | |

| Average working Power | 350W | |

| Net weight | 130KG | |

| Packing size | 0.82CBM | |

TVM925S (customized model) SMT pick and place machine 4heads 50slots With Rail Benchtop SMT Pick&Place Machine

The TVM925S pick and place machine is designed with 4 heads,50 slots.

-

Wave soldering output conveyor QJ400-BO

-

Benchtop Manual Smt Frameless PCB Solder Paste Stencil Printer Printing Machine

-

SMT Manual Frameless Pcb Solder Paste Stencil Printer

-

SMT frameless steel stencil screen printing table

-

Nitrogen generator, used for selective welding

-

Desktop selection welding QSO-300B

-

Desktop Selective Wave Soldering Machine QH-SHSS341

-

SMT semi-automatic pick and place machine with Dispenser

-

SMT X-Ray Intelligent Item Counting Machine

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other smt pick and place machine products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/