Description

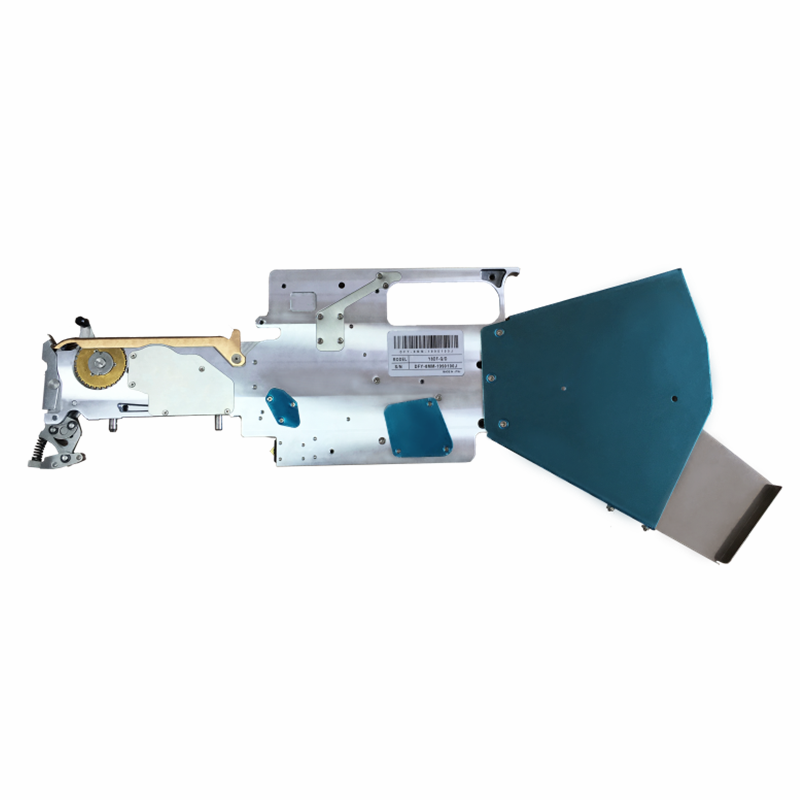

Pneumatic SMD feeders which is called pick and place feeder are going to be replaced by electric feeders because that the electric SMD feeders adopt a stepper motor as the actuator instead of the pneumatic cylinder.

In many applications, an electric actuator is preferred other than the pneumatic or hydraulic cylinder because of high repeat precision, lower maintenance requirement, and so on privileges.

The ground pick and place machine from China is still using the pneumatic feeders, But for the higher grade like the TVM92S, QM61, and QM81 which can carry up to 80 SMD feeders, Electric SMD Feeders will be the right choice.

Feeder performance will degrade without proper maintenance. Regular cleaning, lubrication, and calibration are essential.

Feeder bad maintenance will lead to:

- Mispicking of parts

- Misplacement of parts

- “Tombstoning” of parts

- Flipped parts

Issues related to improper nozzle/feeder maintenance or the use of poor quality nozzles. Here are some of the most common problems:

- Poor pickup location on part. It will cause a loss of vacuum and result in parts shifting on the nozzle during transport.

- Short/worn nozzles result in poor pickup and can cause the part not to be embedded into the paste. When the part is not placed into the paste correctly there is not enough surface tension to hold the part while the PCB is moving. Parts will shift.

| Electric Feeder Size | Suitable for |

| 8MM Electric Feeder | belt width is 8mm, 0201, 0402, 0603, 1206, 0805, 3014, 3528, 4148, SOT23 and other using less SMD components, 1210 resistance. |

| 12MM Electric Feeder | belt width is 12mm, LED pick and place machine, 5050 lamp beads, 5730 lamp beads, 5630, 4014. |

| 16MM Electric Feeder | belt width is 16mm, two-terminal and 16mm wide tape packaged components. |

| 24MM Electric Feeder | belt width is 24mm, two-terminal and 24mm wide tape packaged components. |

| 32MM Electric Feeder | belt width is 32mm, two-terminal and 32mm wide tape packaged components. |