Description

| Model | QSX-250 |

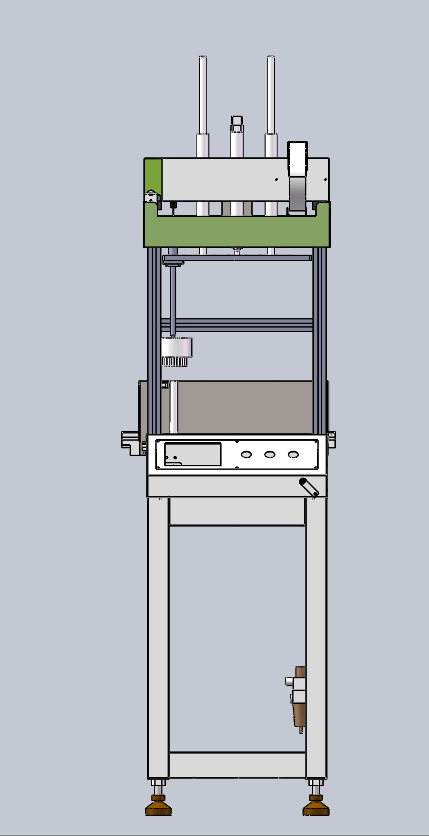

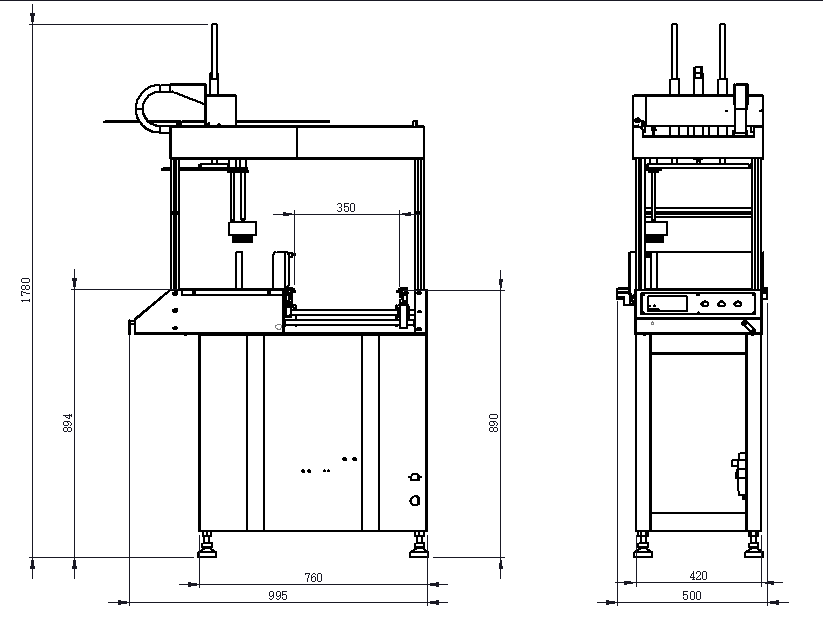

| Dimension(L*W*H) | Length 500 * width 995 * height 1780mm |

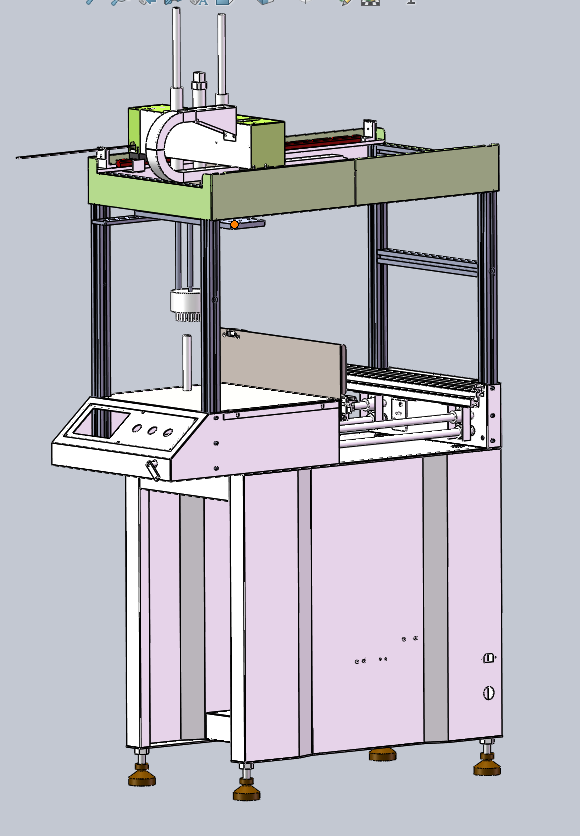

| Control Systems | PLC non standard customization |

| Rail width(W) | 50-350mm |

| Substrate size( L*W) | minimum L50 × W50mm; maximum L350 × 250mm |

| The thickness of the PCB substrate | 0.4mm -5mm |

| Duty Cycle run time | 9-12 second |

| Orbital altitude | 910 ± 30 mm |

| Conveyor type | 57 step + arbitrary sucker (patented) flat belt transportation |

| Conveyor direction | Left to right L → R, anterior fixationor left to right R→L anterior fixation |

| Conveyor speed | 100~1000mm/ minute |

| Total Power | 150W |

| Normal Power Consumption | 40W |

| Weight | 300KG |

| Electric Supply Required | 2-phase\220V 50/60Hz (2-phase\220V 50/60Hz ) |

Characteristic:

1、The length of the standard machine is only 0.5m;

2、 In the process of working, the plate can be added, and there is no need to stop the machine;

3、No material box is needed for single panel;

4、PLC + man-machine touch screen control is adopted;

5、57 step + any suction cup (patent) belt transportation (without adjusting the suction cup position, the stability is 0.05%);

6、The width is adjusted manually, which is simple and intuitive;

7、 It must be an excellent gold partner to match with the frame board machine. (1.4 m long for single side and double side PCB);

8、It can completely replace the all-in-one sucking board machine, and the probability of card is almost zero;

9、It is also very simple to change the transmission direction with the combination of gas and electricity;

10、Compared with the traditional suction machine, it is more energy-saving, and the power is less than 100W;

11、The plate can be added during the working process without stopping the machine

12、No boxes are required for double and single panels

13、PLC + human-machine touch screen control is adopted

14、Double motor lifting, the board can be inserted at will, and it can be automatically corrected even if it is tilted;

15、The motor is powerful, and the lifting of more than 50 plates on the heavy pallet is still stable and smooth;

16、More energy efficient than a traditional plate machine, with power less than 100W.