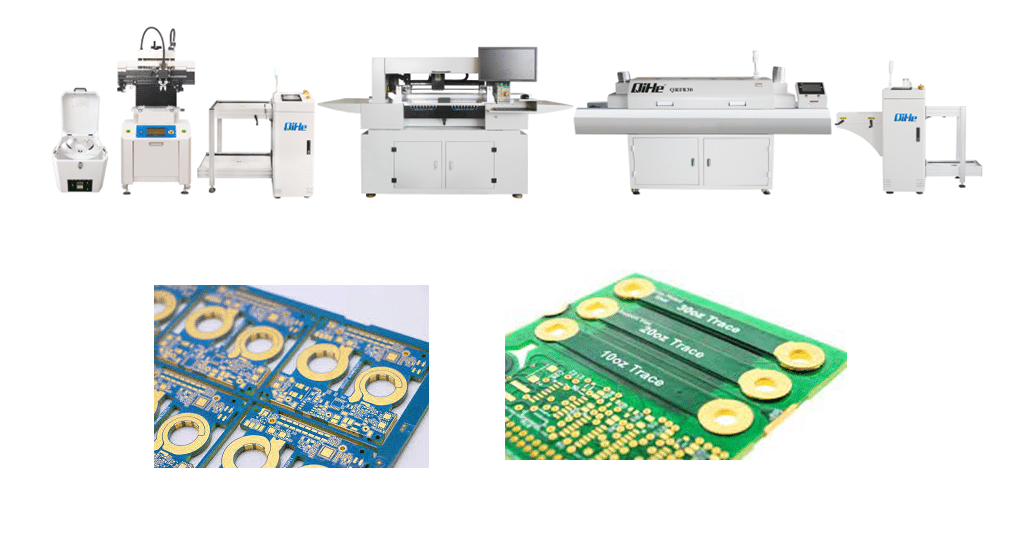

Today author from QiHe smt pick and place machine sharing you with Copper Thickness Production in PCB Hole and Explanation of Problems.

PCB circuit board double-sided circuit board will need to sink copper in the hole,

Make the via hole have copper and become a via hole.

However, during the production process, the manufacturer will occasionally find that there is no copper in the hole after the copper sinking or the copper is not saturated.

Now the author of qhsmt will briefly describe several reasons.

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,welcome to send inquiry.

The reasons for the occurrence of holes without copper are nothing more than:

- Drilling dust plugs the hole or the hole is thick.

- There are bubbles in the potion when copper is deposited, and copper is not deposited in the hole.

- There is line ink in the hole, no protective layer is applied, and there is no copper in the hole after etching.

- The acid-base potion in the hole is not cleaned after copper sinking or electroplating, and the parking time is too long, resulting in slow corrosion.

- Improper operation, staying too long in the micro-etching process.

- The pressure of the punching plate is too high,

(the designed punching hole is too close to the conductive hole) and the center is disconnected neatly. - Poor penetration of electroplating chemicals (tin, nickel).

Improvements are made for these 7 reasons for the occurrence of hole-free copper problems. - Add high-pressure water washing and desmearing processes to the holes that are prone to dust (such as 0.3mm or less hole diameter including 0.3mm).

- Improve the potion activity and vibration effect.

- Change the printing screen and alignment film.

- Extend the washing time and stipulate how many hours to complete the graphics transfer.

- Set the timer. 6. Add explosion-proof holes. Reduce the stress on the board.

- Regular penetration test.

Then, knowing that there are so many reasons that lead to no copper open circuit in the hole,

do we still need to slice and analyze it every time?

Whether it should go to preventive supervision in advance.

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,smt pick and place machine,pnp,pick&place,pcb assembly,smd chip shooter,pnp machine,chip mounter,smt line,welcome to send inquiry

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line. - Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line. - Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.