Description

The core function of the automatic coating machine is to apply the paint accurately and evenly on the surface of the workpiece through automated equipment, so as to achieve high precision, high efficiency and standardization of the coating process. It is widely used in electronics, automobiles, aviation and other fields, which can prevent moisture and corrosion, improve the performance of the workpiece, and reduce material loss and labor costs.

| Model | Automatic coating robot | |

| Trip | 300*300*100mm(Customizable itinerary) | |

| Programing mode | Import teaching programming orgraphics | |

| Movable graphics track | Point,line,are,circle,curve,multiple lines,spiral,ellipse | |

| Glue valve type | Cone valve/Fan valve /Dispensing valve/Needle atomizing valve /Water curtain valve)(optional | |

| Coating width | 1-30mm | |

| Barrel volume | 1L/5L/10L(Optional capacity) | |

| The glue frequency | 5times/SEC | |

| Load | X/Y axle load | 10kg |

| Z axle load | 5kg | |

| X/Y/Z Axial dynamic speed | 0~600mm/sec | |

| Resolving power | 0.01mm/Axis | |

| Repeated positioning accuracy | Screw drive | 0.01~0.02mm |

| Synchronous belt drive | 0.02~0.04mm | |

| Program record mode | At least 100 groups,5000Points each | |

| Display mode | LCD teaching box | |

| Motor system | Japan precision micro stepping motor | |

Drive mode | Guide | Taiwan upper silver linear guide rail |

| Wire rod | Taiwan silver bar | |

| Belt | Italy Lartey synchronous belt | |

| X/Y/Z axis synchronous belt for standard configuration,Z axis screw rod is optional,X/Y/Z axis screw rod for customization | ||

| Motion filling function | Three dimensional space any route | |

| Input power | Full voltage AC110~220V | |

| External control interface | RS232 | |

| Motor control shaft number | 3/4/5/6 axis | |

Axis range | X axis | 300/400/500/600/700/800… (Customized) |

| Y axis | 300/400/500/600/700/800.. (Customized) | |

| Z axis | 100/150/200(Customized) | |

| R axis | 360°,can be rotated in two dimensions | |

| Outline size(mm) | Length (X-axis travel + 250mm) * width (Y-axis travel + 300mm) * height 600mm | |

| Weight(kg) | 45/65175/85kg | |

-

SMT X-Ray Intelligent Item Counting Machine

-

High-temperature Industrial Ovens 250°C to 500°C Industrial Drying Ovens Intelligent Constant Temperature Industrial Ovens

-

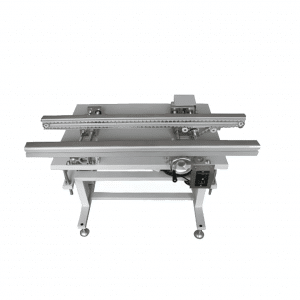

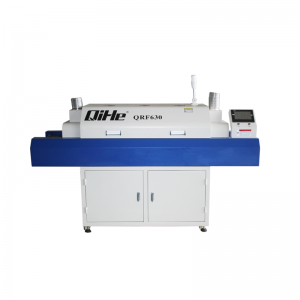

Wave Soldering In-Board feeder machine QJ350-BI

-

PCB drying cabinet 240L

-

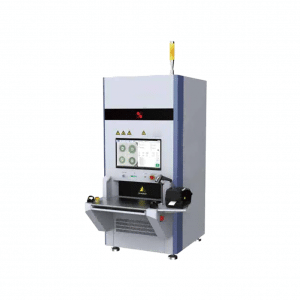

Automatic coating robot

-

Miniature board suction machine QSX-250

-

Professional PCB external vacuum packaging machine , moisture-proof and anti-oxidation, protecting the quality of circuit boards

-

High – Precision Offline PCBA Cleaner QH-800: Remove Stubborn Flux Residue Completely

-

Low cost cost-effective SMD component point counters