Description

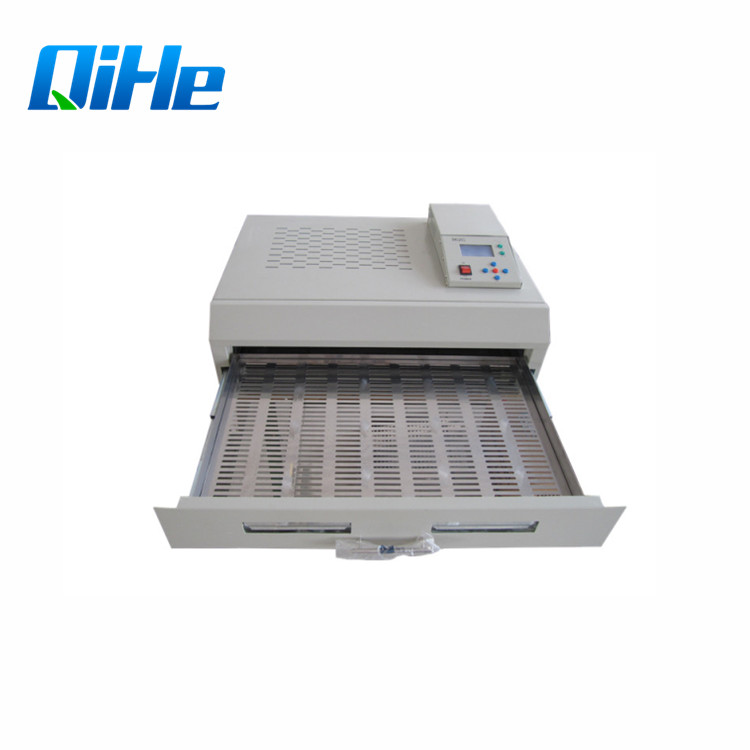

QR962C Desktop SMT Reflow Oven solder welding Maximum Soldering Area: 400*600 mm

Suitable for small laboratories, offices, personal design and processing

1. desktop SMT Reflow Oven solder welding Mixed Process

1. Single-sided mixing process: (Plug-in and surface-mount components are on the A side of the PCB) Incoming material inspection -> Solder paste mixing -> PCB A-side silk-screen solder paste -> Patch -> A-side reflow soldering – > PCB A-side plug-in -> Wave soldering or dip soldering (a small number of plug-ins can be soldered by hand) -> (Cleaning) -> Inspection -> Rework (first post-inserted)

2. Double-sided mixing process: (surface mount components on the A side of the PCB, plug-in on the B side of the PCB)

A. Incoming material inspection -> solder paste mixing -> PCB A-side silk screen solder paste -> patch -> reflow soldering -> PCB B-side plug-in -> wave soldering (a small number of plug-ins can be hand soldered) -> (cleaning )-> Inspection -> Rework

B. Incoming material inspection -> PCB A-side silk-screen solder paste -> SMD -> Manual pad on the A side of the PCB pad solder paste -> PCB B-side insert -> Reflow soldering -> (cleaning) – > Inspection -> Rework (surface mount components on the A and B sides of the PCB, plug-in on either or both sides of the PCB) Surface mount components on both sides of the A and B sides of the double-sided PCB by double-sided assembly Reflow soldering, then manual soldering of the two-sided insert

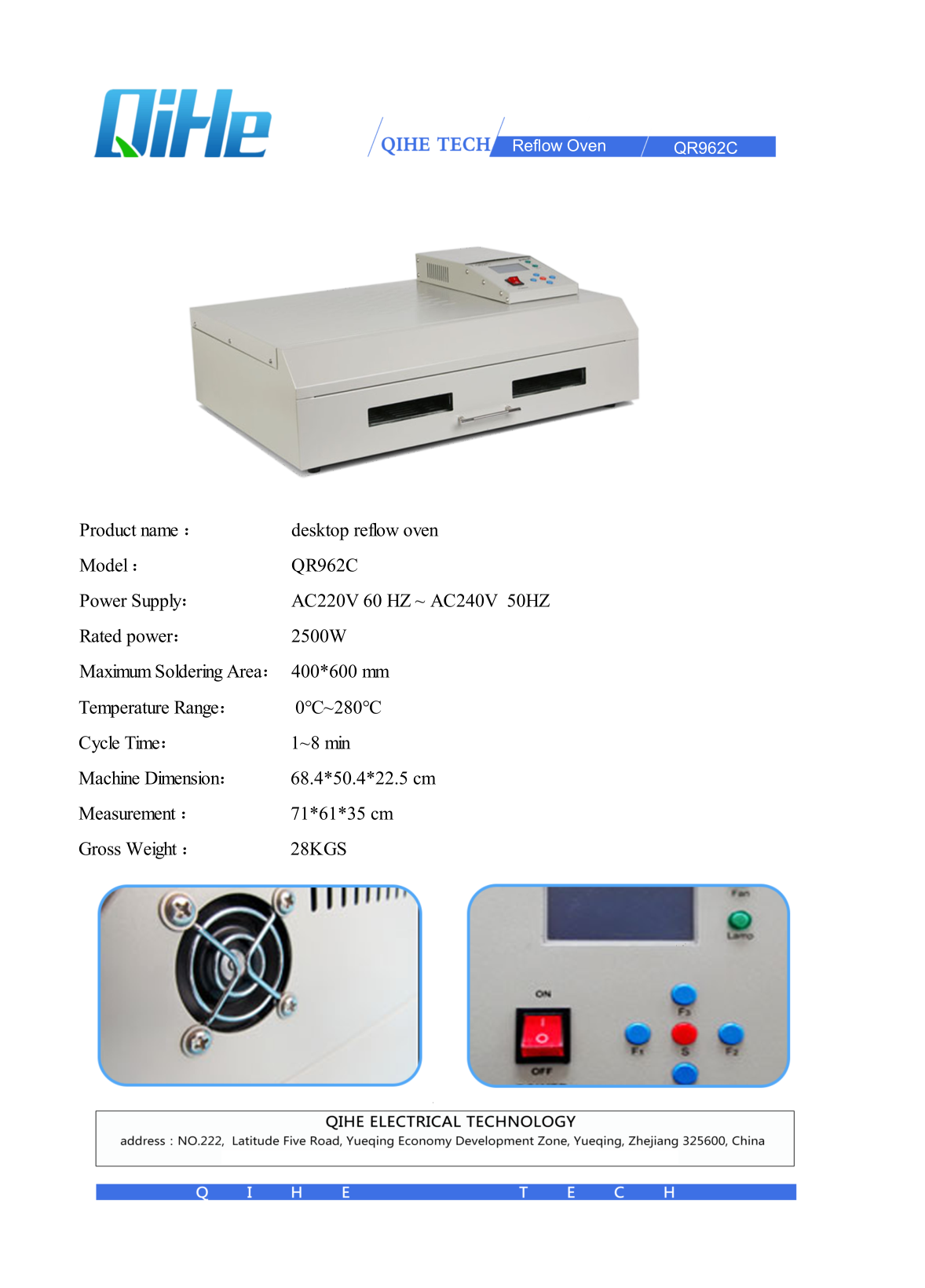

| Product name | desktop reflow oven |

| Model | QR962C |

| Power Supply | AC220V 60 HZ ~ AC240V 50HZ |

| Rated power | 2500W |

| Maximum Soldering Area | 400*600 mm |

| Temperature Range | 0℃~280℃ |

| Cycle Time | 1~8 min |

| Machine Dimension | 68.4*50.4*22.5 cm |

| Measurement | 71*61*35 cm |

| Gross Weight | 28KGS |