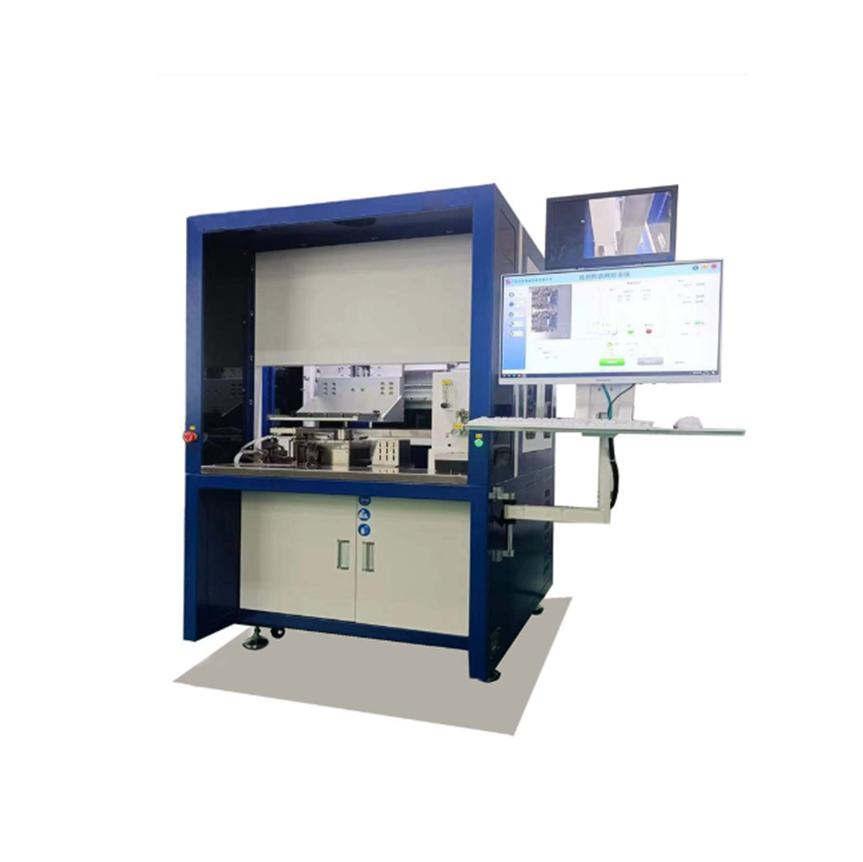

Description

Function

Through the high-speed moving precision welding head, non-contact local welding is performed on the specified solder joints/areas of the circuit board, replacing the whole board welding, which is suitable for the rapid welding and rework of large-scale, high-precision electronic components.

Advantages

High efficiency and high speed:

fast welding speed, support for mass production, and greatly improve production capacity.

Precise and controllable:

high positioning accuracy, can set personalized welding parameters (temperature, time, solder amount), reduce the risk of thermal damage.

Flexible and economical:

offline operation does not occupy the production line, adapts to multiple varieties of changeover, saves solder and labor costs.

Yield improvement:

local welding avoids the influence of high temperature on the whole board, improves the reliability of solder joints and product yield.

| Specifications | Parameter |

| Overall Dimensions | 1430L*1000W*1650H(mm) |

| Machine frame | Steel structure+baking paint |

| Operating height | 900±20mm |

| Weight | Approx.380KG |

| Power supply | 1φ 220V 50/60HZ |

| Total power | 7.5KW |

| Taking and placing board method | Manual taking and placing |

| Machine appearance | Closed-type |

| Programming methods | Picture programming,Gerber document,video teaching programming, etc |

| Welding real-time monitoring | Standard configuration |

| Operating mode | PCB board XYZ axis movement |

| PCB parameter | |

| PCB size | Min:30(L)*30(W);Max:400(L)*300(W)(mm) |

| Top component height | Max100mm |

| Bottom component height | Max30mm |

| PCB Weight | Max10Kg |

| PCB Process Edge | >3mm |

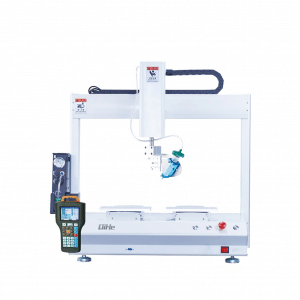

| Selective spray system | |

| Spray movement mode | PCB movement in XYZ axis |

| Spray flux volume | 1L |

| Spray flux add mode | Manual |

| Spray nozzle type | Needle |

| Spray cycle time | 1 Sec/soldered dot(The minimum spray time can be set to 0.1 seconds) |

| Spray movement precision | ±0.1mm |

| spray moving speed | 0-500mm adjustable |

| Spray flow control | pressure gage +flow valve |

| Preheating system | |

| Preheating method | bottom heat |

| Heating form | Infrared spotlight heating |

| Temperature control | Heating rate ratio and time |

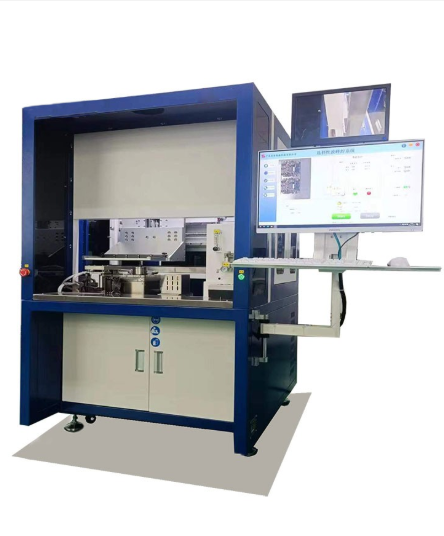

| Selective Soldering System | |

| Welding movement mode | PCB movement in XYZ |

| Movement mode | Servo motor +linear rail |

| Number of soldering heads | One |

| Solder feeding mode | Manual |

| Solder capacity | 15KG |

| Solder melting time | 45min |

| Solder power | 1.2KW |

| Solder nozzle size | Standard with 5 solder tips(3-64-86-108-1210-14) |

| Solder cycle time | 1~5Sec/soldered dot |

| Temperature control mode | PID+SSR |

| Temperature setting range | Max350℃ |

| Temperature accuracy | ±2℃ |

| Waver height | Max 0-8mm |

| Welding precision | ±0.1mm |

| Solder dross | 0.2Kg/8H(Not N2 protection);0.01Kg/8H(N2 protection) |

| N2 protection system | |

| N2 protection mode | Nozzle and solder pot |

| N2 consumption | 1.5M³/h(Nitrogen concentration>99.999%) |

| N2 flow control | Glass rotor flowmeter |