Description

RF8835LS reflow oven CHB temperature control meter is used to control the instrument operation interface, PID temperature adjustment, easy to operate: intelligent control system is adopted, the temperature control accuracy is high ±1-2°C, and the control system is stable and reliable;

Equipped with mesh belt tensioning device, the transportation is stable, no shaking, no deformation, ensuring smooth transportation of PCB;

All heating zones are PID controlled by temperature control table (the upper 8 temperature zones and the lower 8 temperature zones have independent temperature control, which can be opened separately by different temperature zones. The heating can be divided into zones to reduce the starting power);

With fault sound and light alarm function;

Equipped with leakage protector to ensure the safety of operators and control system;

Built-in board ejection and automatic delay shutdown system to ensure that the PCB and reflow soldering machine will not be damaged when the power is cut off or overheated;

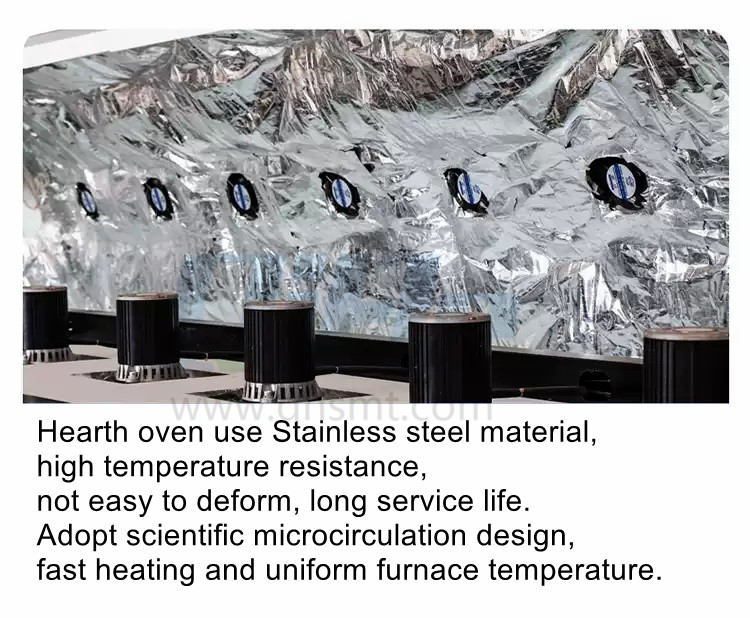

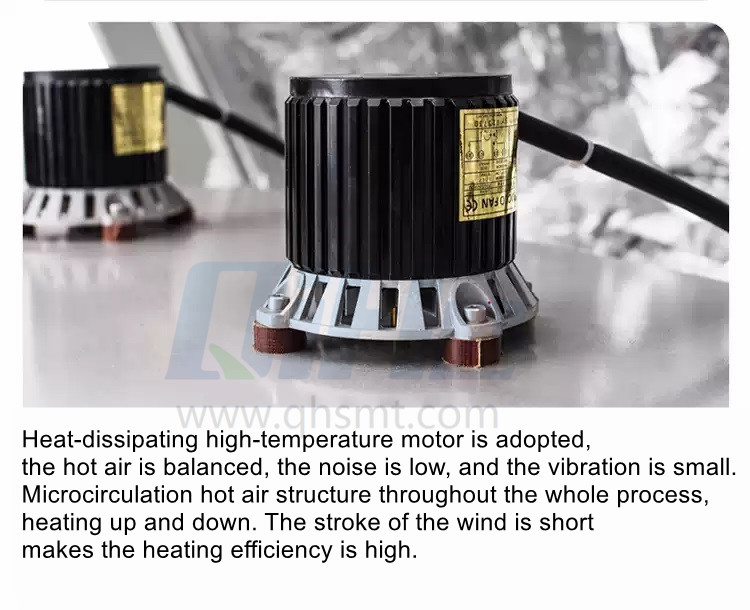

Adopt hot air circulation heating method, uniform temperature, high thermal compensation efficiency, high-efficiency pressurized acceleration air duct, greatly increase the flow of circulating hot air, rapid temperature rise (about 20 minutes), high thermal compensation efficiency, and high-temperature welding and curing;

The 8 upper and lower temperature zones are equipped with independent temperature sensing sensors to monitor and compensate the temperature balance of each temperature zone in real time;

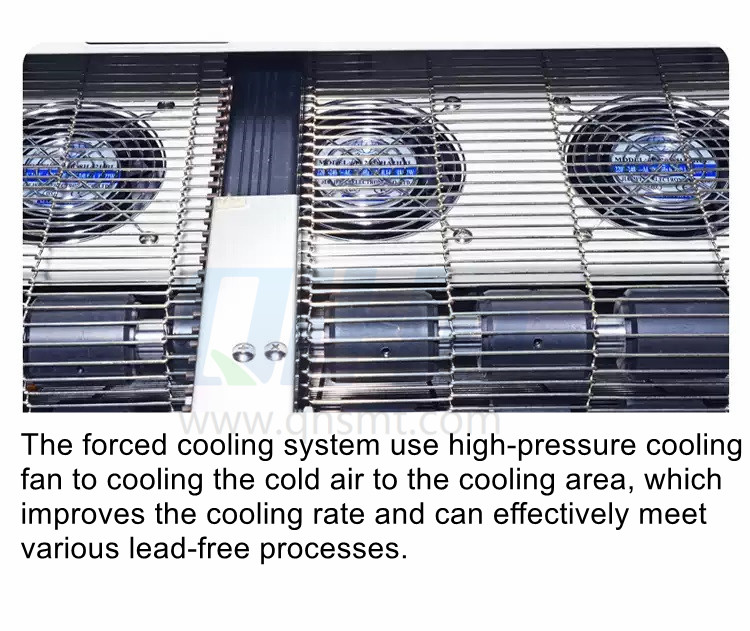

The rapid cooling system from the international technology adopts the magnifying glass type centralized high-efficiency rapid cooling, the cooling speed can reach 3.5~6℃/second, and the management is very convenient; the external forced cooling device ensures the crystallization effect of solder joints (Option optional, the standard configuration is forced natural air cooling);

Special pressurized air transport structure and special-shaped heating wire design, no noise, no vibration, high heat exchange rate, the temperature difference Δt between the bottom of the BGA and the PCB board is extremely small, which best meets the strict requirements of the lead-free process , especially for lead-free products with high difficulty soldering requirements.

About RF835LS reflow oven

| Heating area number, | up8/down8 |

| Heating zone length, | 2800 mm |

| Heating mode, | full hot air |

| Number of cooling zone, | 2 |

| PCB maximum width, | 350 mm |

| Transportation direction, | left to right (or right to left) |

| The height of conveyor belt, | 880±20mm |

| Transmission Mode, | network transmission |

| Conveyor belt speed, | 0-1800mm/min |

| power supply, | 380V 5 line 3 phase 50/60 hz |

| Start the power, | 18kw |

| Normal work power, | 5 kw |

| Heating time, | about 15 minutes |

| Temperature control range, | Room temperature to 350 ℃ |

| emperature control mode, | Temperature meter control |

| Temperature control precision | ±1℃ |

| PCB temperature deviation, | ±2℃ |

| Abnormal alarm, | temperature anomalies |

| Appearance size (length * width * height), | 4200 * 710 * 1300mm |

| Machine weight, | 550 kg |

What is SMT ?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/