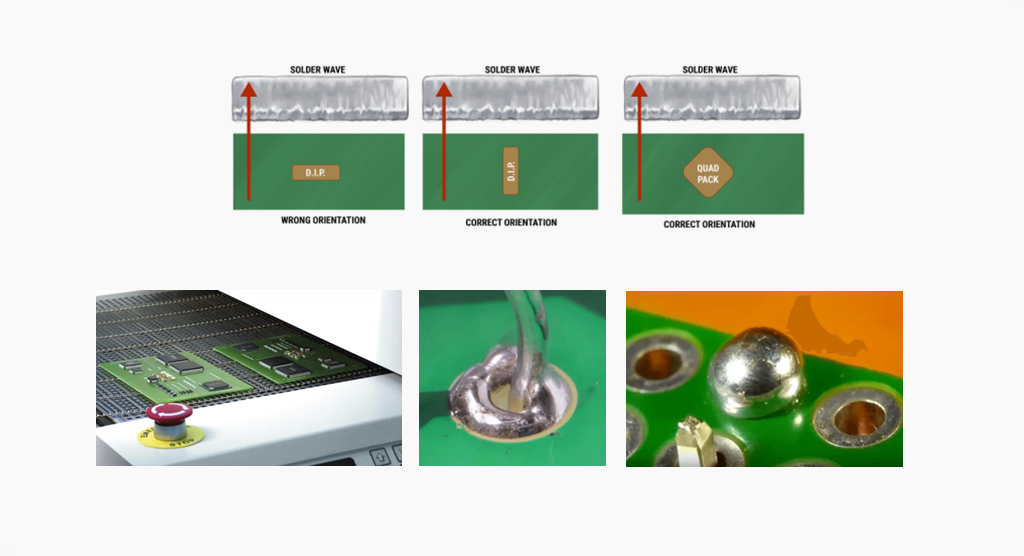

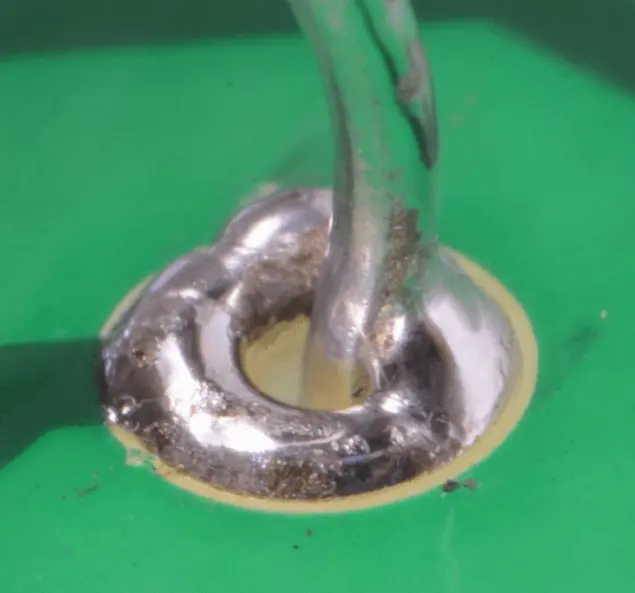

Today author from qihe smt pick and place machine tell you about it with you .The reasons for Solder skip when the PCBA has been processed by wave soldering are:

- The activity of solder paste is weak;

- The copper-platinum spacing is too large or the copper-paste small components are too large;

- The flatness of the component feet is not good (warped feet, deformation)

- PCB copper and platinum are too dirty or oxidized;

- The PCB board contains moisture;

- There are perforations on the PCB copper and platinum

The solution to wave soldering Solder Empty

There are many reasons why Solder skip occurs in PCBA over wave soldering, and specific problems need to be analyzed in detail

The solution can be found by carefully arranging and finding the cause on the spot. The following solutions can be tried.

- Feed back the bad PCB board to the supplier or steel mesh and set the pad spacing to 0.5mm;

- Clean the PCB with flux;

- The machine blows too much air and blows the solder paste away;

- Component oxidation;

- Solder skip is caused by the solder paste of the board edge components being wiped off during the flow-drawing process;

- The hole is large and the pin is too thin.

The above is the introduction of the DIP plug-in process of smt chip processing manufacturers common problem.

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly