In smt patch processing, there are some small knowledge that cannot be ignored.

This also belongs to the knowledge of smt patch processing, which is easily overlooked by people.

Next, the technicians of Qihe smt pick and place machine sorted out some knowledge about smt patch processing for us.

- Generally speaking, the regular temperature of the SMT patch processing workshop is 25±3°C;

the - When printing solder paste, the required materials and items are: solder paste, scraper, steel plate, wiping paper, cleaning agent, dust-free paper, mixing knife;

the - The solder paste alloy composition is generally Sn/Pb alloy, and Sn accounts for 63%, Pb accounts for 37%;

the - The main ingredients in solder paste are divided into two categories: tin powder and flux;

the - The primary role of flux in soldering is to remove oxides, damage the surface tension of molten tin, and prevent re-oxidation.

the - The volume ratio of flux and tin powder particles in solder paste is 1:1, and the weight ratio is about 9:1;

the - The principle of taking solder paste is first in first out;

the - When the solder paste is unpacked and used, it must go through two important processes: warming up and mixing;

the - The common production methods of steel plates are: etching, laser, electroforming;

the - The full name of SMT chip processing is Surface mount (or mounting) technology, which means surface adhesion (or mounting) technology in Chinese;

the - ESD is the English abbreviation of “Electrostatic discharge”, which means “electrostatic discharge” in Chinese;

the - When writing an SMT placement machine program, the program contains five types of data, namely: PCB data; Mark data; Feeder data; Nozzle data; Part data;

the - The melting point of lead-free solder Sn/Ag/Cu (96.5/3.0/0.5) is 217°C;

the - The relative temperature and humidity of the parts drying box should be less than 10%;

the - Commonly used passive components (Passive Devices) include: resistors, capacitors, point senses (or diodes), etc.; active components (Active Devices) include: transistors, ICs, etc.;

the - The common material of SMT stencil is stainless steel;

the - The thickness of SMT steel mesh is 0.15mm;

the - The types of electrostatic charge generation are different, conflict, induction, electrostatic conduction, etc.; the impact of electrostatic charge on the smt chip processing industry is: ESD failure, electrostatic pollution; the three principles of static electricity elimination are electrostatic neutralization, grounding, shielding .

the - Inch standard 0603 means lengthwidth is 0.06inch0.03inch, metric standard 3216 means lengthwidth is 3.2mm1.6mm;

- QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,welcome to send inquiry.

smt pick and place machine

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

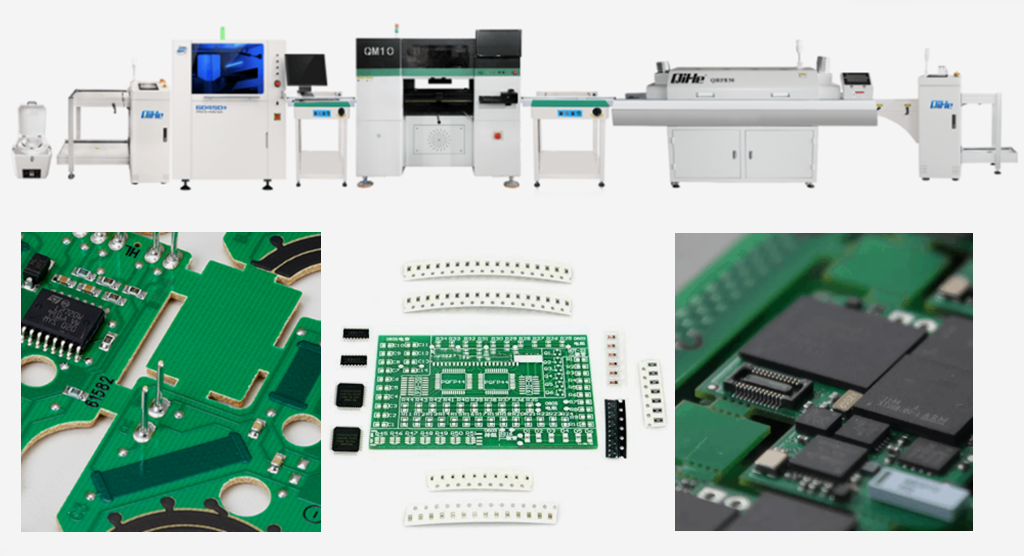

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.