The lighting control system is developing more and more toward the direction of automation and intelligence, and its flexibility and precision are getting higher and higher. From DDC (Direct Digital Control), DCS (Distributed Control System) to FCS (Field Bus Control System), the system The degree of networking has been continuously enhanced, and the unified automatic control of the control system and the network system has been gradually realized, which has important practical significance for the research on the fieldbus-based intelligent lighting control system. qihe led machine sharing you some with control protocol that intelligent lights use .

The basic content of the fieldbus-based intelligent lighting control system, whether it is a traditional lighting control system or an automatic lighting control system, is connected in a point-to-point manner, and each control point is connected to a control line. The number of cables is extremely large, and the construction is difficult, which can easily cause waste of manpower, material resources, and financial resources. If the control method needs to be adjusted according to actual needs, the entire line needs to be rectified.

In the fieldbus-based control system, the control box or lighting switch exists in the fieldbus as a network node, and the fieldbus plays the role of a hub. Fieldbus enables communication.

In the control system, monitoring nodes such as network hosts can perform necessary detection and control on the equipment in the system. The main nodes in the intelligent lighting control system include intelligent relays, intelligent dimmers, intelligent switches, intelligent hosts, upper PCs, etc. Other nodes may also include image acquisition equipment, sound acquisition equipment, and illuminance sensors. Each node has a CPU to implement functions such as storage, communication, and fault diagnosis.

Bus types and communication protocols that can be used in intelligent lighting control systems

C-bus

C-bus is a two-wire closed bus protocol, including two twisted pairs, introduced by Qisheng Company. A pair of wires should not only realize the transmission of bus device information, but also realize power supply (DC15V-DC36V). In the C-bus bus, the bus devices can communicate directly without the help of the central controller.

Its transmission protocol is CSMA/CD, the basic unit is a subnet, and there are three topological structures, one is bus, the other is tree, and the third is star. Each subnet can accommodate 225 control loops or 100 units, its transmission distance can reach 1000 meters, and the communication rate can reach 9.6kbps. Hubei Xiantao Gymnasium carried out lighting design based on the application of this protocol, and the intelligent control effect is good.

i-bus

The i-bus is based on the standard EIB of the European installation bus and belongs to a two-wire network.

Most homes or buildings in Europe design automation control systems according to EIB standards. The EIBA organization is mainly responsible for managing the EIB agreement. This organization has obvious non-profit and neutrality. Manufacturers can produce related products as long as they apply to the EIBA organization and agree to abide by the agreement.

Dynet

The Dynet system is controlled by Dlight software. It is a four-wire protocol and includes two pairs of twisted pairs. One pair of twisted pairs is responsible for providing power (DC12V) for the device, and the other pair is responsible for the transmission of device information.

In order to make comprehensive preparations, it is generally recommended to use Category 5 wires during bus installation. Except for 4 pairs of twisted-pair wires, the redundant wires are reserved for future use. The transmission protocol of Dynet is based on the RS485 four-wire system. The topology structure is only one type of bus. connection, the number of equipment units is also 64. In this system, the transmission rate of the main network is at most 57.6kbps, while that of the subnet is 9.6kbps.

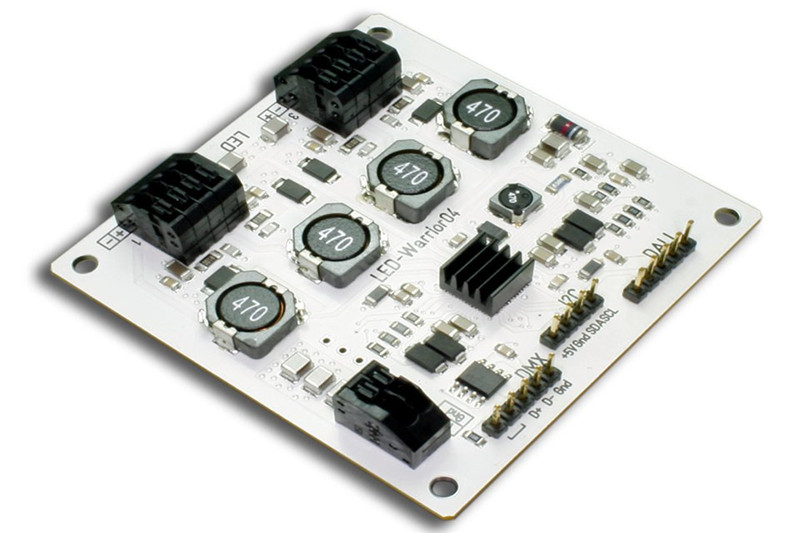

DALL

DALL is a digital addressable dimming interface. This protocol was included in the IEC60929 standard (1994). Since then, relevant international manufacturers, such as fixture manufacturers, lamp manufacturers, and chip manufacturers, have given great support to it Great support and recognition.

Philips perfected part of the agreement in 1999, and also manufactured smart lighting products based on the agreement. The control system designed on the basis of DALL has the main features of simplicity and clear structure, and the high-performance lighting and intelligent lighting required in the room can be realized on the basis of this protocol. Its functions include status display, scene, dimming, switching, etc., and the ballast is the controlled object in the system.

HBS

HBS is also called the home bus system. Japanese companies took the lead in proposing this agreement. This agreement can realize the interconnection between telephones, lighting equipment, video, audio and other devices, and use coaxial cables or twisted pairs to realize the contents of this agreement. Realize the automation and integration of household appliances.

The HBS agreement also comprehensively considers the content of remote services, including distance teaching, telemedicine and shopping within the home. This protocol can realize the control of simple analog quantities and electrical switching quantities through a dedicated bus, and its advantages are low risk, strong anti-interference, low cost, and fast response.

DMX512

The DMX512 protocol is a digital multiplexing protocol, which is neither a national standard nor an industry standard. It was proposed by USITT. This protocol was originally used for compatible processing of theater or stage controllers and dimmers.

Its advantages are strong practicability and simple operation, so many manufacturers in the world recognize this agreement. When designing or producing digital dimming equipment, more and more attention is paid to the application of the DMX512 protocol in China. Whether it is a theater, a stage, or a dimmer used in a studio, digital control can be carried out with the support of this protocol system. The role of this protocol is more prominent in a master-slave control system. This protocol is reliable. High, simple operation, unobstructed information access and other remarkable features.

X-10

The X-10 protocol is widely used in North America. It relies on the power line carrier technology for control and has high practicability. Whether its transmission work can be carried out smoothly mainly depends on the 120kHz pulse signal. When the power signal passes through the zero point, observe whether the pulse signal is generated, and then confirm that the signal can be transmitted. In the process of transmission, 1110 is the identifier in the form of true value displayed by the header of the signal frame, while other signals are transmitted in the AC point and exist in the form of complement code or true value in the zero phase. The advantage of this protocol is that it is easy to use and applicable to reconstruction projects.

What is the control protocol that intelligent lights use?

The intelligent lighting control system is the product of the development of science and technology. Compared with the traditional lighting control design, the lighting control system based on the field bus has strong advantages. It is convenient to use and has strong adaptability. monitoring and management. There are many types of related protocols in the market, such as C-bus, i-bus, Dynet, DALL, HBS, DMX512, X-10, etc. Although there are many types and significant advantages, there are certain differences in the environment and conditions applicable to each protocol. In order to expand the scope of application of the system, unified industry standards and related specifications should be formulated.

Best seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

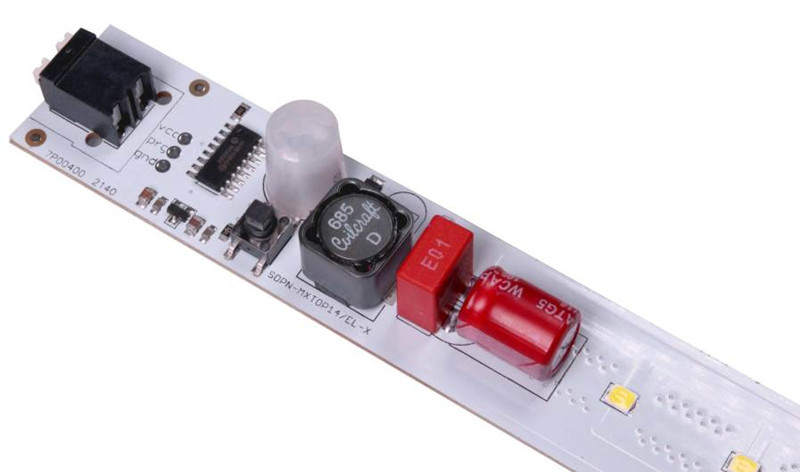

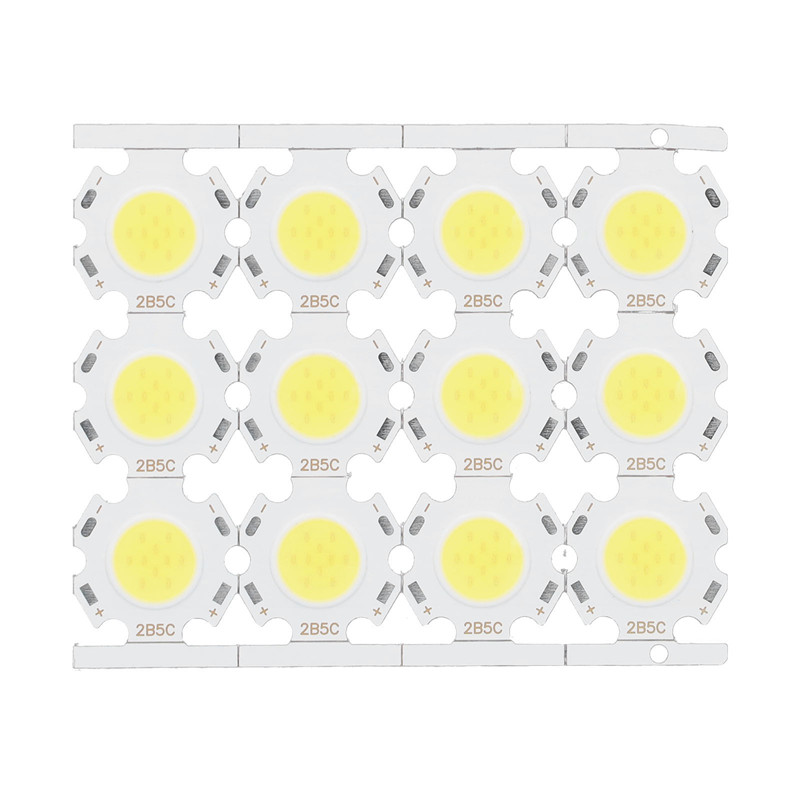

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

How to choose the right smt pick and place robot?

SMT Pick and place robots can execute virtually all smd material handling operations both cost-efficiently and effectively — With several designs and configurations available in the market, it can be challenging to pick one that suits your operational needs. To help you make the right decision, some factors and features you should look out for when purchasing a pick and place robot.The most important thing is the operating system, then the hardware configuration, the types of components supported, and the speed of operation, the accuracy of placement, and the smt setup cost of the entire smt line .

Qihe smt pick&place machine is a professional operating system independently developed. It has more than ten years of user experience, combined with the algorithm improvement of world-renowned colleges, and the most advanced flying camera and motion system. It is your best choice. The system is friendly for beginners and professionals.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/