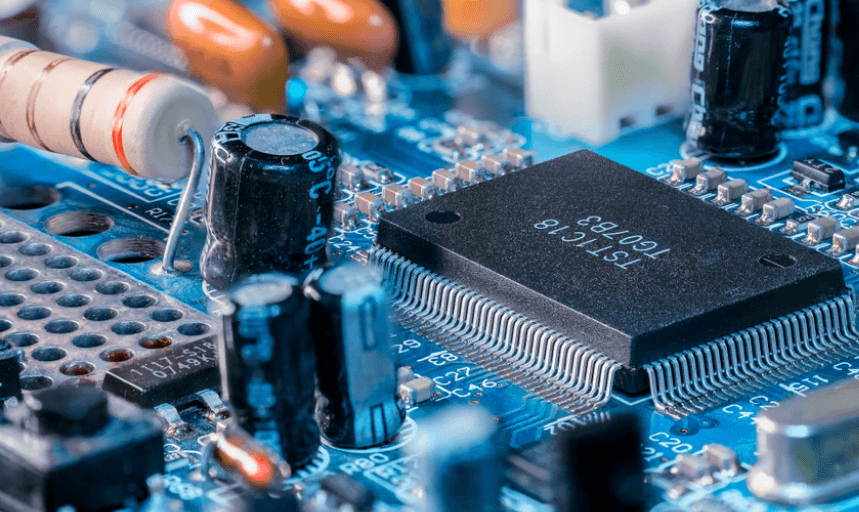

SMD capacitors are used as passive components, and their functions are often used in power circuits: to achieve bypass, decoupling, filtering and energy storage, etc. The main functions in signal circuits are coupling, oscillation/synchronization and time constant role. Qihe pick and place will explain each of these separately.

Filtering function in the power circuit

Filtering is a very important part of the function of chip capacitors. It is used in almost all power supply circuits. Theoretically (that is, assuming that the capacitor is a pure capacitor), the larger the capacitor, the smaller the impedance, and the higher the passing frequency. But in fact, most of the capacitors exceeding 1uF are electrolytic capacitors, which have a large inductance component, so the impedance will increase when the frequency is high.

Sometimes it is seen that there is a large electrolytic capacitor connected in parallel with a small capacitor. At this time, the large capacitor passes the low frequency, and the small capacitor passes the high frequency. The function of the capacitor is to pass high resistance to low, pass high frequency to block low frequency. The larger the capacitance, the easier it is for low frequencies to pass, and the larger the capacitance, the easier it is for high frequencies to pass. Specifically used in filtering, a large capacitor (1000uF) filters low frequencies, and a small capacitor (20pF) filters high frequencies.

A friend once compared the filter capacitor to a “pond”. Since the voltage across the capacitor will not change suddenly, it can be seen that the higher the signal frequency, the greater the attenuation. It can be said that the capacitor is like a pond, and the water volume will not change due to the addition or evaporation of a few drops of water. It converts changes in voltage into changes in current. The higher the frequency, the greater the peak current, thereby buffering the voltage. Filtering is the process of charging and discharging.

The bypass capacitor

The bypass capacitor is an energy storage device that provides energy for local devices. It can even out the output of the voltage regulator and reduce the load demand. Like a small rechargeable battery, the bypass capacitor can be charged and discharged to the device. To minimize impedance, bypass capacitors should be placed as close as possible to the power and ground pins of the load device. This is a good protection against ground potential rise and noise caused by excessively large input values. Ground bounce is the voltage drop across a ground connection when a large current spike is passed through it.

Remove decoupling

Remove decoupling, also known as decoupling solution. From a circuit point of view, it is always possible to distinguish between the source of the drive and the load being driven. If the load capacitance is relatively large, the drive circuit needs to charge and discharge the capacitance to complete the signal transition. When the rising edge is relatively steep, the current is relatively large, so that the driving current will absorb a large power supply current. The inductance and resistance (especially the inductance on the chip pins will bounce back), this current is actually a kind of noise compared to the normal situation, which will affect the normal operation of the front stage. This is coupling.

The decoupling capacitor is to play the role of a battery to meet the change of the drive circuit current and avoid mutual coupling interference. It will be easier to understand by combining bypass capacitors and decoupling capacitors. The bypass capacitor is actually decoupling, but the bypass capacitor generally refers to a high-frequency bypass, that is, to provide a low-impedance leakage prevention path for high-frequency switching noise. High-frequency bypass capacitors are generally small, generally 0.1u, 0.01u according to the resonant frequency, and decoupling capacitors are generally relatively large, 10uF or larger, determined according to the distribution parameters in the circuit and the change of the driving current. Bypass is to filter out the interference in the input signal, while decoupling is to filter out the interference in the output signal to prevent the interference signal from returning to the power supply. This should be their essential difference.

The energy storage capacitor

The energy storage capacitor collects the charge through the rectifier, and transmits the stored energy to the output terminal of the power supply through the converter lead. Aluminum electrolytic capacitors with a voltage rating of 40-450VDC and a capacitance value between 220-150 000uF are more commonly used. According to different power requirements, devices are sometimes connected in series, in parallel or in combination. For power supplies with a power level exceeding 10KW, generally larger pot-shaped screw-terminal capacitors are used.

Read more: What is the purpose of a chip capacitor?Best seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/