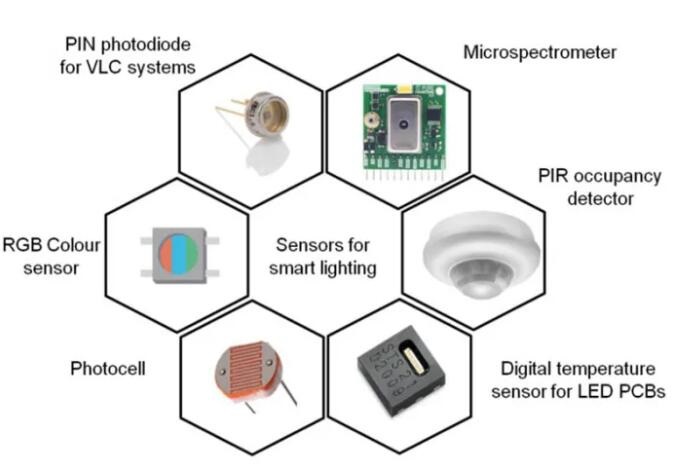

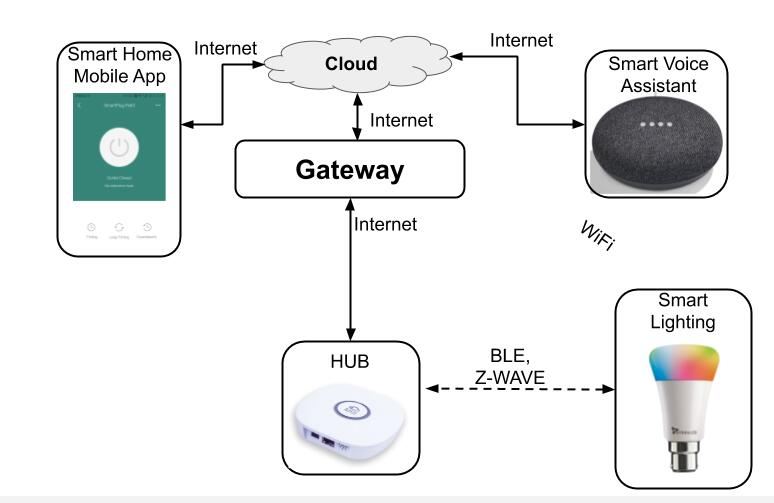

Smart lights are Wi-Fi-enabled devices that connect to the internet using wireless networks. Certain smart light bulbs require a dedicated smart hub to connect with wirelessly, with the hub then plugging into an internet router. The hub also acts as a gateway between the smart light and your phone or tablet.Light sensing smart devices can turn off the light switch when you don’t remember to and smart bulbs let you set lighting schedules. Today qihe smt pick and place machine sharing So, even if you forget to turn the basement light off, a light sensor will do it for you Commonly Used Sensors of LED Smart Lighting.The biggest difference between LED lighting fixtures and traditional lighting fixtures is that LED lighting fixtures are a complete electronic product, while traditional lighting fixtures are only an electrical product. Therefore, LED lamps can be easily associated with various types of sensors to achieve various automatic control functions such as light control and infrared control. For example, the automatic switch of LED street lights can be easily realized with a photosensitive sensor; for community night walkways and courtyard lighting, infrared sensors can be used to collect human activity information and automatically turn on and off lighting fixtures.

Automatic control of LED lighting switch

Sensors are devices for signal acquisition and electromechanical conversion, and their electromechanical technology is quite mature. In recent years, the rise of MEMS (micro-electromechanical systems) technology has made sensor technology make great strides toward miniaturization, intelligence, multi-function, and low cost. Various types of sensors, such as photosensitive sensors and infrared sensors, can be combined with LED lighting fixtures to form an intelligent control system. The sensors convert the collected physical quantity signals into electrical signals, which can be passed through integrated circuit AD (analog-to-digital) converters. , MCU (microcontroller), and DA (digital-to-analog) converters intelligently process the collected signals to control the turning on and off of LED lighting fixtures. Humans can use this to set various control requirements on the MCU to control the switching time, brightness, color rendering, and colorful changes of LED lights, so as to achieve the goal of saving electricity and energy. System block diagram composed of sensors and LED lamps. The current integrated circuit manufacturing technology can already integrate AD, DA, and MCU in a 5mm×5mm or smaller package, and it is very convenient to install in the lamp without occupying an area.

Photosensitive sensor and LED lighting combination

Wind and solar LED street lamps are highly intelligent and unattended road lighting fixtures. They use wind and sunlight to generate electricity and use batteries to store energy. Therefore, automatic energy management is very important. Photosensitive sensors are ideal electronic sensors that can control the automatic switching of circuits due to changes in illumination at dawn and dusk (sunrise and sunset).

Photosensitive sensors can automatically control the opening and closing of LED lighting fixtures in shopping malls based on weather, time period and region. In bright daylight, by reducing its output power to reduce power consumption, a convenience store with a store area of 200m2 can reduce power consumption by up to 53% compared with when fluorescent lamps are used. The lifespan is also about 50,000 to 100,000 hours. Under normal circumstances, the service life of LED lighting fixtures is about 40,000 hours; the color of the light can also be changed in RGB (red, green, blue) to make the shopping malls more colorful and the atmosphere more active; Compared with the original blue LED, the purple LED using red, green and blue phosphors has higher color rendering.

Infrared sensor and LED lamp combination

Infrared sensors work by detecting infrared rays emitted by the human body. The main principle is: the 10μm infrared rays emitted by the human body are enhanced by the Fresnel filter lens and then gathered on the pyroelectric element PIR (passive infrared) detector. When the person is active, the emission position of the infrared radiation will change. The component will lose the charge balance, and the pyroelectric effect will release the charge to the outside. The infrared sensor converts the change of the infrared radiation energy passing through the Fresnel filter lens into an electrical signal, that is, thermoelectric conversion. When no human body moves in the detection area of the passive infrared detector, the infrared sensor senses only the background temperature. When the human body enters the detection area, through the Fresnel lens, the pyroelectric infrared sensor senses the temperature of the human body and The difference in background temperature, after the signal is collected, is compared with the existing detection data in the system to determine whether someone is really waiting for the infrared source to enter the detection area.

Passive infrared sensors have three key components: Fresnel filter lens, pyroelectric infrared sensor and matching low-noise amplifier. The Fresnel lens has two functions: one is focusing, that is, to refract the pyro-infrared signal on the PIR; the other is to divide the detection area into several bright areas and dark areas, so that moving objects/people entering the detection area can A changing pyro infrared signal is produced on the PIR in the form of temperature changes. Generally, a low-noise amplifier is also matched. When the ambient temperature on the detector rises, especially when it is close to the normal body temperature of the human body (37°C), the sensitivity of the sensor decreases, and the gain is compensated by it to increase its sensitivity. The output signal can be used to drive electronic switches to realize switch control of LED lighting circuits.

Ultrasonic sensors, which are similar to infrared sensors, have been used more in automatic detection of moving objects in recent years. Ultrasonic sensors mainly use the Doppler principle to emit high-frequency ultrasonic waves beyond the perception of the human body through the crystal oscillator. Generally, 25~40kHz waves are typically used, and then the control module detects the frequency of the reflected waves. If there is an object moving in the area, the reflected There will be a slight fluctuation in the wave frequency, that is, the Doppler effect, in order to judge the movement of the object in the lighting area, so as to achieve the purpose of controlling the switch.

The longitudinal oscillation characteristics of ultrasonic waves can propagate in gas, liquid and solid, and their propagation speeds are different; it also has refraction and reflection phenomena, with lower propagation frequency and faster attenuation in air, but attenuation in solid and liquid Smaller and spreads farther. Ultrasonic sensors utilize these characteristics of ultrasonic waves. Ultrasonic sensors have the characteristics of large sensitive range, no visual blind zone, and no interference from obstacles. This technology has been used in the commercial and security fields for more than 25 years, and has been proven to be the most effective method for detecting the movement of small objects. Therefore, the system composed of LED lamps can sensitively control the switch.

Due to the high sensitivity of the ultrasonic sensor, air vibration, ventilation, heating and cooling system and the movement of the surrounding adjacent space will cause false triggering of the ultrasonic sensor, so the ultrasonic sensor needs to be calibrated in time.

Temperature sensor for over-temperature protection of LED lamps

The temperature sensor NTC (Negative Temperature Coefficient) was widely used as an over-temperature protection for LED lamps earlier. If LED lamps use high-power LED light sources, they must use multi-wing aluminum radiators. Due to the small space of LED lamps for indoor lighting, heat dissipation is still one of the biggest technical bottlenecks. If the heat dissipation of LED lamps is not good, it will cause the LED light source to decay early due to overheating. After the LED lamp is turned on, the heat will also be enriched to the lamp head due to the automatic rise of hot air, which will affect the life of the power supply. Therefore, when designing LED lamps, an NTC can be placed close to the aluminum radiator close to the LED light source to collect the temperature of the lamp in real time. When the temperature of the aluminum radiator of the lamp cup rises, this circuit can be used to automatically reduce the output current of the constant current source. Cool down the lamp; when the temperature of the aluminum radiator of the lamp cup rises to the limit setting value, the LED power supply is automatically turned off to realize over-temperature protection of the lamp. When the temperature drops, the lamp is automatically turned on again.

Conclusion

Because LED lamps are a complete electronic product, as the structure of LED lamps diversifies, applications expand, and with more creativity and innovation in the design of LED lighting lamps, more sensors will be combined and applied in LED lighting and into the lighting project system. A new era of intelligent LED lighting is coming, and the lighting life of human beings will become brighter and more comfortable.

Read more: Commonly Used Sensors of LED Smart LightingBest seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place,,pick and place machine easy operation manual,placer,pick and place machines,what is smt machine,smt machine price,smt machine supplier,openpnp,used pick and place machine,smt line,pick and place robot,high speed pick and place,double sided smt assembly,pcb pick and place,paste mixer machine,smt nozzle,smt mounter machine,smt line,smt pick and place machine diy,smt process,smt setup,chip mounter,pnp machine,smd chip shooter,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,smt pick and place machine,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,mini smt mounter machine,liteplacer,tabletop smt line,tabletop pnp,desktop pnp machine,desktop pick&place machine,tvm802bx,tvm802b,tvm802ax,tvm802a,LED Smart Lighting,Commonly Used Sensors,pick and place,pick and place,

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/