Input resistance is a performance indicator used to measure the impact of an amplifier on a signal source. The larger the input resistance, the smaller the current the amplifier draws from the signal source, and the larger the signal voltage obtained at the input end of the amplifier, that is, the signal source voltage is less attenuated. Theoretical basis: Us=(Rs+Ri)*I. Rs is the signal source internal resistance, Ri is the amplifier input resistance. Therefore, the amplifier circuit of an oscilloscope, voltmeter and other instruments used to measure signal voltage should have a large input resistance. If you want to draw a larger current from the signal source, you should make the amplifier have a smaller input resistance. Today qihe smt pick and place machine sharing the meaning of input resistance and output resistance

The output resistance is used to measure the load capacity of the amplifier. When the amplifier outputs the amplified signal to the load resistor RL, for the load RL, the amplifier can be equivalent to a signal source with internal resistance Ro. This signal source provides the output signal voltage and output signal current to RL. Ro is called the output resistance of the amplifier, which is the AC equivalent resistance seen from the output end of the amplifier to the amplifier itself.

If the output resistance Ro is very small and meets the condition of R0<>RL, then when RL changes within a large range, the output signal current can be maintained constant. The ability of an amplifier to maintain a constant output signal voltage (or current) under different load conditions is called load capability. The output resistance Ro is a performance indicator that characterizes this ability.

The common collector amplifier, also known as the emitter follower, has a large input resistance and a small output resistance (generally a few ohms or hundreds of ohms). In order to reduce the output resistance value, you can choose a tube with a large B value. A smaller output resistance indicates a strong load capacity. When the load changes within a large range, the output signal voltage can basically be maintained constant. The common collector circuit cannot amplify the voltage signal (always less than 1), but it can amplify the current signal and amplify the power.

This circuit is often used in multi-stage amplifier circuits as an input stage with high input impedance, an output stage with low output impedance, or as a buffer stage to achieve impedance transformation. For example, before performing correlated double sampling after the linear array CCD output, a first-level emitter follower must be connected to increase the current and improve the ability to drive the subsequent circuit. Because the signal source resistance will affect the output resistance of the circuit, the influence of the signal source internal resistance Rs should be considered. In addition, the load resistance RL will affect the input resistance Ri, which should be paid attention to when analyzing and designing the amplifier circuit.

The voltage amplification factor of the common emitter amplifier circuit is larger, and the output signal voltage is inverse phase with the input signal voltage. Its current amplification factor is also relatively large. His input resistance and output resistance are large and appropriate. This kind of circuit is often used in places where there are no special requirements for input resistance and output resistance. It is used as the input stage, intermediate stage or output stage of general low-frequency multi-stage amplifier circuits.

The voltage amplification factor of the common base amplifier circuit is also relatively large, and the output signal is in the same phase as the input signal voltage. Its current amplification factor is less than 1 and it cannot amplify the current. The input resistance of this circuit is small and the output resistance is moderate. Because of its good frequency characteristics, it is often used in wide-band amplifiers and high-band amplifiers.

Read more: Understanding Input and Output ResistanceBest seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

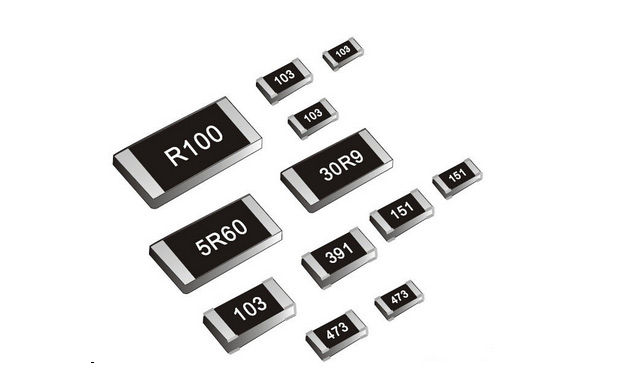

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/