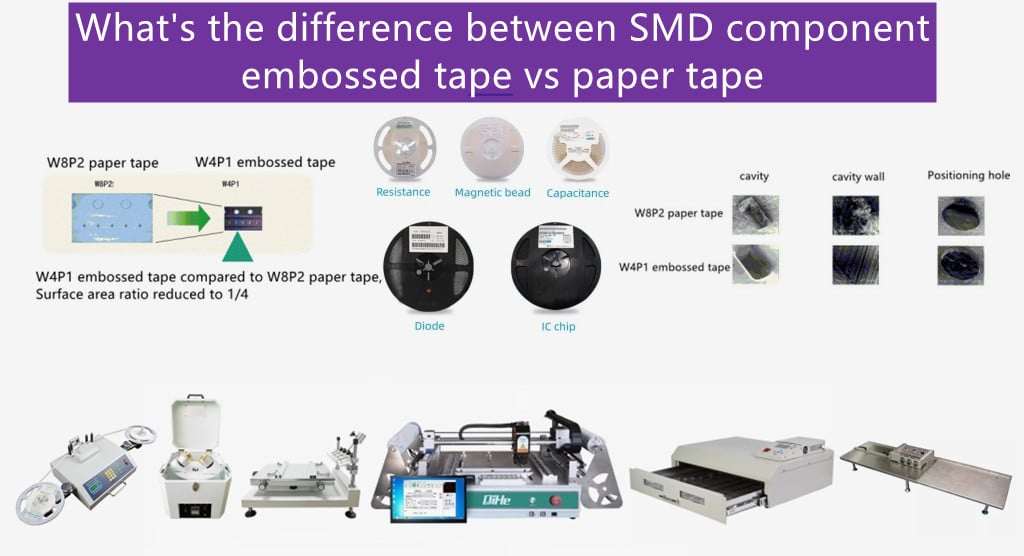

Each product has its own packaging method and packaging identification. For students who have not come into contact with a complete Murata capacitor packaging disk, the seemingly very simple Murata chip electronic material packaging disk actually has a lot of tricks. The following is an explanation based on the narrow embossed tape corresponding to the 0402 size in SMD electronic materials.Today qihe smt pick and place machine sharing what’s the embossed tape vs paper tape difference

SMD electronic material packaging based on the concept of environmental protection has the following advantages:

Environmental protection response: reduce the use of packaging resources, reduce packaging waste, and reduce energy consumption during transportation.

To save mounting space: reduce the space used for storage and reduce the space used by the placement machine material machine

Dust-free mounting response: Prevent paper scraps and dust from causing problems at the welding joint, and prevent static electricity from causing picking problems.

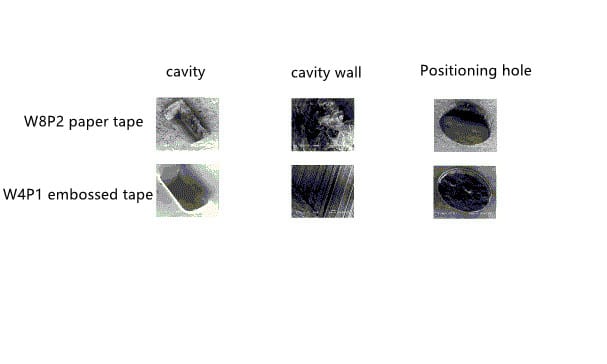

Mounting stability response: high stability of taping cavity, stable supply of ultra-small chip components

Take the following example as an example:

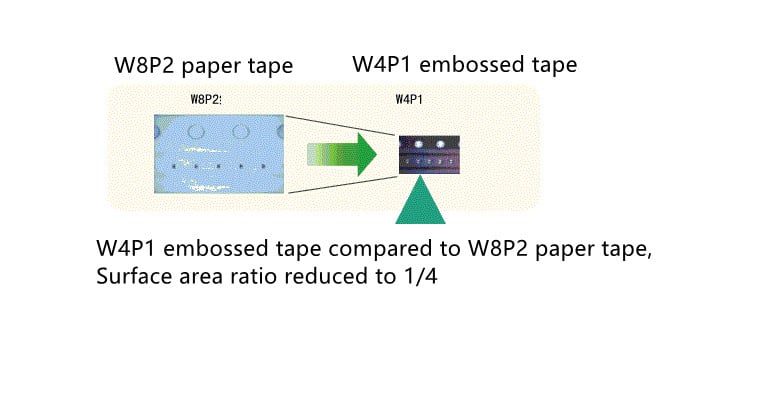

Compared with W8P2 paper tape, W4P1 embossed tape reduces the packaging material size (in terms of surface area ratio) of the same component to 1/4. This greatly reduces the waste of packaging materials during the placement process. In addition, by reducing the packaging size, transportation energy consumption and carbon dioxide emissions are also reduced accordingly.

For sheet component packaging of the same size, the embossed tape W4P1 is narrower than the W8P2 paper tape, and the spacing is correspondingly reduced, so that the tape area can be more fully utilized. This greatly reduces the storage space of components.

When chip components packed with paper tape are put into the placement machine, the fluff and dust of the paper tape may cause defects in the welds of ultra-small components. Embossed tape made of plastic can solve this problem. It can provide a dust-free space for the placement of ultra-small chip components, meet the different needs of various circuit board placements, and is very flexible.

Because embossed tape generates less lint and paper dust than existing paper tape packaging, it can prevent cavities from clogging. This solves the picking problem.

Read more: What’s the difference between SMD component embossed tape vs paper tapeBest seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/