Today qihe smt pick and place machine sharing Components of PCB Circuit Protection . Circuit protection components have a wide range of applications. As long as there is electricity, it is necessary to install circuit protection components,

such as various household appliances, home audio-visual and digital products, personal care and other consumer electronics, computers and their peripherals, mobile phones and Its peripherals, lighting, medical electronics, automotive electronics, electricity, industrial equipment, etc., cover all aspects of people’s production and life.

Circuit protection is essentially a failsafe that’s designed to protect people and properties if an electrical fault occurs. Every electrical circuit has a maximum voltage or amperage. If this is exceeded, the wire overheats, potentially causing the wire insulation to melt and fire to break out.

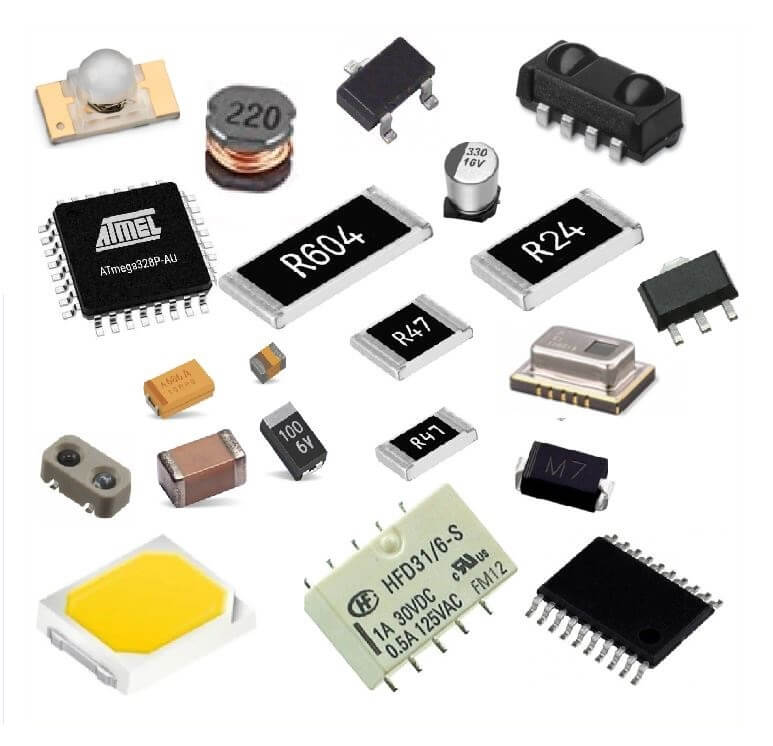

Circuit Protection Components are devices used to protect the circuit from overcurrent and overvoltage (static electricity) in the secondary circuits of electronic equipment. Chip type protectors to meet the requirements for high density surface mounting technology, and more suitable for making compact equipment.

As an electronic engineer, you must not only be very proficient in circuits, but you must at least be able to understand circuits and know the role of circuit protection devices. When customers raise protection needs, you can promptly provide effective and implementable rectification suggestions.

There are two main forms of circuit protection: overvoltage protection and overcurrent protection. Selecting appropriate circuit protection devices is the key to achieving efficient and reliable circuit protection design. When it comes to the selection of circuit protection devices, we must know the role of each circuit protection device.

When selecting circuit protection devices we need to know that the protection circuit should not interfere with the normal behavior of the protected circuit. In addition, it must prevent any voltage transients from causing repetitive or non-repetitive unstable behavior of the entire system.

Lightning protection overvoltage devices are divided into clamping overvoltage devices and switching overvoltage devices.

Switching overvoltage devices are well-known lightning protection devices: ceramic gas discharge tubes, semiconductor discharge tubes and glass discharge tubes; clamping type overvoltage devices Voltage devices include transient suppression diodes, varistors, chip varistors and ESD discharge diodes; overcurrent devices are mainly PTC component self-restoring fuses. The following are their specific functions:

The role of the discharge tube: The discharge tube is often used in the first or first two stages of a multi-level protection circuit to discharge lightning transient overcurrent and limit overvoltage. The discharge tube limits the voltage to a lower level. Thereby playing a protective role. Electronics’ discharge tubes are divided into gas discharge tubes and solid discharge tubes.

Gas discharge tubes are mainly ceramic gas discharge tubes and glass gas discharge tubes. In specific applications, the selection of discharge tube types and models requires engineers to select based on product applications. Determine the protection level of the port and related selection parameters.

The role of the transient suppression diode: The transient suppression diode can change the high impedance between its two poles into a low impedance at a speed of 10 negative 12 seconds, absorb surge power up to several kilowatts, and reduce the resistance between the two poles.

The voltage clamp is at a predetermined value, effectively protecting precision components in electronic circuits from damage by various surge pulses.

The role of the varistor: The varistor is a voltage-limiting protection device. The nonlinear characteristics of the varistor are mainly used in circuit protection. When overvoltage occurs between the two poles of the varistor, the varistor can reduce the voltage. Clamped to a relatively fixed voltage value to protect the subsequent circuit.

The role of chip varistor: Chip varistor is mainly used to protect components and circuits to prevent ESD generated in power supply, control and signal lines.smt pick and place.

The role of ESD electrostatic discharge diode: ESD electrostatic discharge diode is an overvoltage, anti-static protection component, and is a device designed for I/O port protection in high-speed data transmission applications.

ESD protection devices are used to protect sensitive circuits in electronic equipment from being affected by ESD (electrostatic discharge). Offers very low capacitance, excellent transmission line pulse (TLP) testing, and IEC6100-4-2 testing capabilities.

especially after multi-sample counts up to 1000, thereby improving the protection of sensitive electronic components.smt pick and place.

The function of PTC self-restoring fuse: When the circuit is working normally, its resistance is very small (voltage drop is very small).

When the circuit has overcurrent and its temperature rises, the resistance increases sharply by several orders of magnitude, causing the current in the circuit to is reduced below the safe value so that the subsequent circuits are protected.

When the fault is eliminated, the PPTC element will quickly cool down and return to its original low resistance state, so that it can work again like a new PPTC element.smt pick and place.

The role of the inductor: I believe everyone is aware of the relationship between electromagnetism.

The role of the inductor is that at the beginning of the circuit, when everything is still unstable, if there is current passing through the inductor, an induced current in the opposite direction to the current will definitely be generated ( Faraday’s law of electromagnetic induction), after the circuit has been running for a period of time, everything is stable, the current has not changed, and the electromagnetic induction will not produce current.

At this time, it is stable and there will be no sudden changes. It ensures the safety of the circuit, just like a waterwheel. It rotates slowly due to resistance at first, and then gradually becomes gentle.

Another function of the inductor is to pass DC and block AC. This is not used much, and I don’t know exactly how to use it. I will share it with you when it is used.smt pick and place.

The role of magnetic beads: Magnetic beads have high resistivity and magnetic permeability. They are equivalent to resistance and inductance in series, but the resistance and inductance values change with frequency.

It has better high-frequency filtering characteristics than ordinary inductors. It is resistive at high frequencies, so it can maintain a high impedance over a wide frequency range, thus improving the frequency modulation filtering effect. It is used on Ethernet chips.smt pick and place.

Read more: Components of PCB Circuit Protection | SMDBest seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.Smt pick and place

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost.

Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/