There are some skill of component layout design for PCB smt pick and place machine processing. author from qihe smt pick and place machine will sharing you some tips today .

Circuit board quality problems generally include short circuit and open circuit, green oil blistering, green oil falling off, substrate delamination, board warpage, pad falling off, poor tinning, and open circuit after aging. The fundamental reasons for these common circuit board quality problems are that the production process of the circuit board factory is not up to standard, the production equipment is outdated, the selection of raw materials is poor, and the management is chaotic.

Reason a: The production process is not enough

The production and processing of circuit boards is a relatively high-tech industry, involving a series of interdisciplinary subjects such as electroplating, chemical industry, machinery, etc. Each process of circuit board production and processing must be implemented in accordance with strict production processes. At the same time, each process must be equipped with corresponding testing and laboratory equipment. These process parameters and equipment can ensure the stability of circuit board quality. It is undeniable that the circuit board industry is also a polluting industry. Many practitioners and even bosses who enter this industry are half-way out, so many small circuit board factories only care about the price, as long as the cost can be reduced, in terms of production process and circuit board quality. Don’t care at all. The concentration of the potion in the electroplating process is a parameter that changes all the time. Different types of circuit boards have different current size and time of the electroplating process. These parameters are combined to affect the quality of the circuit board. Only strict production process guidance, production according to process parameters, and continuous laboratory inspection can ensure that the quality of the produced circuit boards is always in a stable state. If the production is organized by experience, there is a quality problem, and the potion is added by feeling, which directly leads to the constant fluctuation of the quality of the circuit board. Customers using this circuit board will have a high repair rate and a low yield, and the surface looks like the circuit board. In fact, the cost of maintenance and repair is greatly increased, and the customer brand is affected, which is not cost-effective in the long run.

Reason b: The selection of raw materials is cheap and inferior

The quality of raw materials is the cornerstone of the quality of the circuit board. What is more hidden now is that the materials used by some circuit board factories are mixed, some are genuine sheets, some are scraps, or recycled materials to dilute the cost. The hidden danger of doing this is not knowing which batch will appear. question. Due to the different use characteristics of circuit boards, some circuit boards do not have high requirements, so some scraps do not show obvious problems in such occasions, which makes many circuit board manufacturers do this by fooling around. At the same time, because of the price The low price has also won the preference of customers. It also encourages circuit board manufacturers to continue to take such risks. In the long run, if the quality of the finished product is caused by the substrate problem, it is often a huge loss, and sometimes it is impossible to restore the company’s reputation and brand. This is also the reason why regular circuit board manufacturers do not do this.

Reason c: The production equipment is backward

The equipment is to ensure the quality from the hardware, increase the investment in the equipment, and make the equipment efficient and stable is the fundamental way to improve the quality of the circuit board. With the advancement of science and technology, the replacement of circuit equipment is getting faster and faster, the equipment is more and more advanced, and of course the price is getting more and more expensive. This has led to the inability of some small circuit board factories to add more expensive equipment, resulting in increased reliance on employees. The current labor cost is already high. Once the dependence on skilled and skilled employees is formed, the management difficulty of the circuit board factory will be greatly increased. Once there is a flow of personnel, the quality of the circuit board will fluctuate.

Reason d: Management confusion: The circuit board factory has many production processes and long cycles

How to achieve scientific and orderly management while reducing management costs is a difficult problem. It is to manage well, manage it well, and manage it cheaply. This requires The long-term accumulation of circuit board manufacturers. With the advancement of science and technology, especially the development of the network, it has become possible to manage the traditional circuit board factory by means of network informatization. Only by making breakthroughs in this regard can core competitiveness be formed. For a factory with poor management, the quality of its circuit boards will naturally fluctuate frequently, and various problems emerge one after another and recur repeatedly.

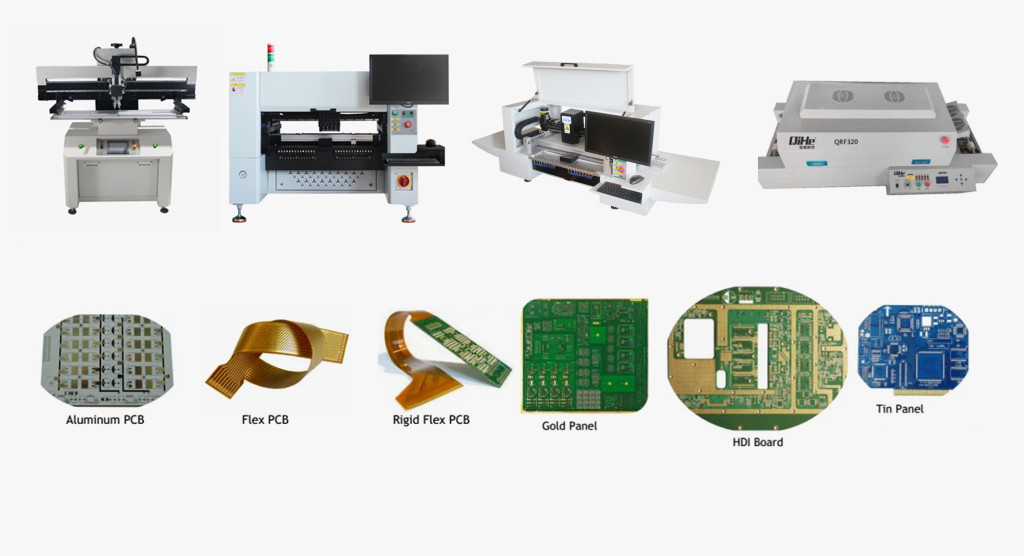

QHSMT is an enterprise specializing in the production of SMT equipment, like pick and place machine ,reflow oven,stencil printer ,welcome to send inquiry

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

you can choose a reflow oven to meets your need like qfr630,qrf835,qrf1235

stencil printer model qh3040,qp3250,qfa5060

Also we have different kinds of smt pick and place machine like tvm802a,tvm802b,tvm802ax,tvm802bx,tvm925s,tvm926s,ql41,qm61,qm62,qm81,qm10

Qihe smt pick and place machine catalog

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

TVM926S (customized model) SMT pick and place machine 4heads 63slots With Rail Benchtop Pick&Place Machine

-

TVM925S (customized model) SMT pick and place machine 4heads 50slots With Rail Benchtop SMT Pick&Place Machine

-

QRF320 / QH320 Crawler-type 5 Zones SMT Reflow Oven solder welding

-

QR962C Desktop SMT Reflow Oven solder welding

-

QH3040 high-precision manual stencil printer

-

QP1068S Semi Automatic Stencil Printing 1.2meters

FAQ for smt pick and place machine

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.

WHAT IS SMT PROCESS?

There are mainly three steps in SMT assembly line process flow: solder paste printing, components placement and reflow soldering.

- Solder Paste Printing

Its function in SMT line process is to print the solder-free paste on the pads of the PCB to prepare for the soldering of the components. The equipment used is a screen printing machine, located at the forefront of the SMT production line.

- Components Placement

Its function is to accurately install the surface mount components on the fixed position of the PCB. The equipment used is a placement machine, located behind the screen printing machine in the SMT production line.

- Reflow Soldering

Its function in SMT manufacturing line is to melt the solder paste so that the surface mount components and the PCB board are firmly bonded together. The equipment used is a reflow oven, located behind the placement machine in the fully automatic SMT production line.