Radio Frequency Identification (RFID, electronic tag) and Near Field Communication (NFC) are two popular keywords, and both belong to tagging technology (Tagging). NFC is developed on the basis of RFID. NFC is essentially no different from RFID. They are both used for signal transmission between two objects that are geographically close.Today qihe smt pick and place machine sharing what is the difference between RFID and NFC technology?

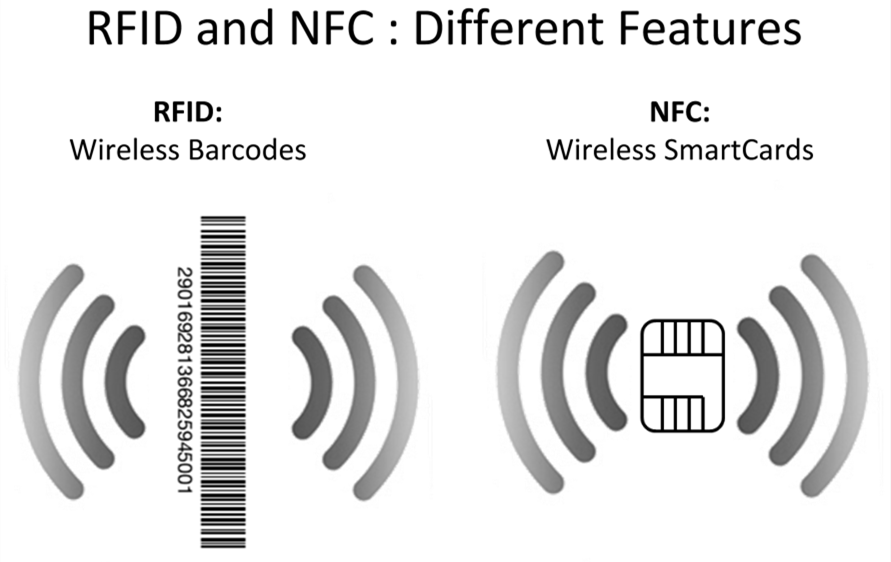

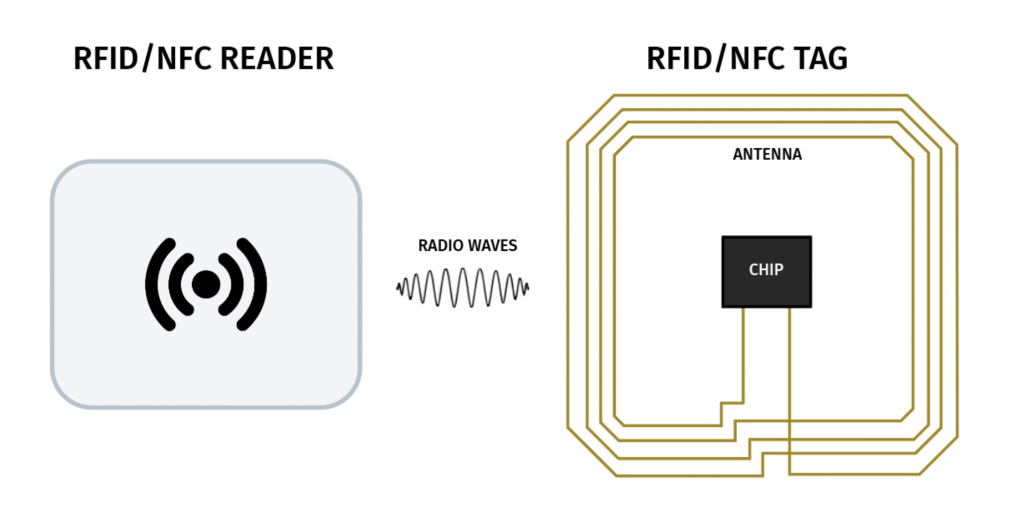

From a professional perspective, RFID is a non-contact identification technology, divided into two types: active and passive. Working principle: The RFID reader emits radio frequency, which passes through the coil of the electronic tag to generate a signal. The reader reads the information and decodes it to complete the entire identification process. In general, active tags (active tags) can also actively send out signals. The RFID system is mainly composed of two types: reader (Reader) and transponder (Transponder).

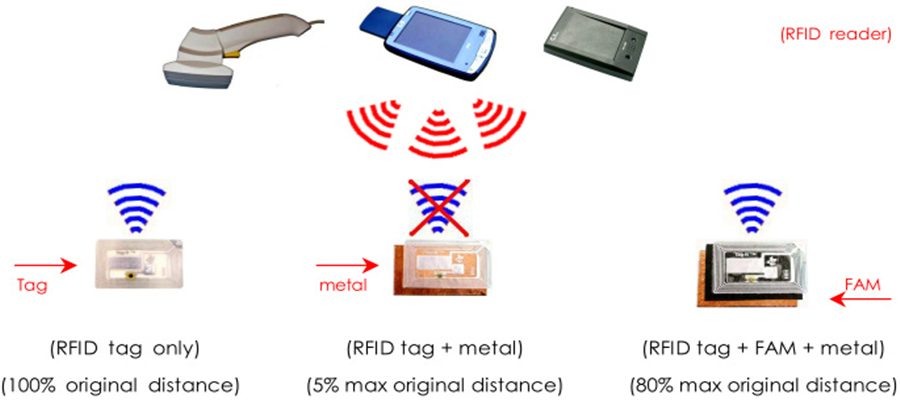

RFID tags can generally be scanned at distances of up to 100 meters and do not require a direct line of sight to the reader. NFC generally requires a direct line of site to the reader, and also requires the communicating devices to be within a few centimeters of each other.

NFC is a technology currently widely used on mobile phones. Working principle: When two NFC devices approach each other within a relatively short distance, they exchange information with each other and complete corresponding transactions and other functions. The biggest feature of NFC is that the reader and transponder are integrated into the same chip. The biggest highlight of NFC technology is the addition of point-to-point communication function, which can quickly establish P2P (point-to-point) wireless communication between Bluetooth devices. NFC devices find each other and establish communication connections. The two devices in P2P communication have a peer-to-peer relationship, while the two devices in RFID communication have a master-slave relationship.

The relationship between the two: From a mathematical perspective, NFC can be considered to be a subset of RFID, that is, RFID with a communication distance within 10cm or 4 inches is NFC. This difference is mainly due to the fact that in some applications specifically designed for cash payment and credit cards, other devices can also receive personal RFID information under the communication distance of RFID, so there are many unsafe factors; and for NFC work, it is effective The distance is about 10cm, so it has high security itself. If you use some special signal collection equipment, you can read RFID information from a considerable distance.

Read more: What is the difference between RFID and NFC technology?Best seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series Q4,TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/