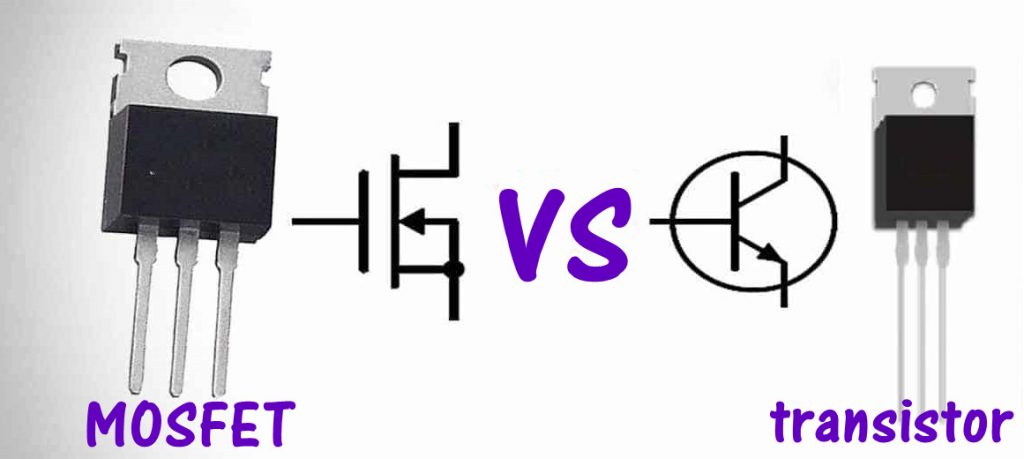

The main advantage of a MOSFET is that it requires almost no input current to control the load current, when compared with bipolar transistors (bipolar junction transistors/BJTs). In an enhancement mode MOSFET, voltage applied to the gate terminal increases the conductivity of the device.Today qihe smt pick and place machine sharing what is the difference between a transistor and a MOSFET.

What are the differences between transistors and MOS tubes when used as switches in circuit design? Working properties:

- Transistors are controlled by current, while MOS tubes are controlled by voltage.

- Cost issue: Transistors are cheap, but MOS tubes are expensive.

- Power consumption problem: Transistors have large losses.

- Driving capability: MOS tubes are often used in power switches and high-current local switching circuits.

In fact, transistors are relatively cheap and easy to use, and are often used in digital circuit switching control.

MOS tubes are used in high-frequency and high-speed circuits, large current situations, and places that are sensitive to base or drain control current.

Generally speaking, in low-cost situations, transistors should be considered first for ordinary applications. If not, MOS tubes should be considered.

In fact, it is wrong to say that current control is slow and voltage control is fast. To truly understand, you need to understand how bipolar transistors and MOS transistors work. Transistors work by the movement of carriers. Take the npn tube emitter follower as an example. When no voltage is applied to the base, the pn junction composed of the base region and the emitter region blocks multiple carriers (the base region is a hole). , the diffusion motion of electrons in the emitter region, an electrostatic field (i.e. built-in electric field) directed from the emitter region to the base region will be induced at the pn junction,

When a positive voltage is applied to the base, the direction of the base area points to the emitter area. When the electric field generated by the applied voltage to the base is greater than the built-in electric field, it is possible for the carriers (electrons) in the base area to flow from the base area to the emitter area. This voltage The minimum value is the forward conduction voltage of the pn junction (generally considered 0.7v in engineering).

But at this time, there will be charges on both sides of each pn junction. At this time, if a positive voltage is applied to the collector-emitter, under the action of the electric field, the electrons in the emitter area will move toward the base area (actually all electrons move in the opposite direction). ), due to the small width of the base area, electrons can easily cross the base area to the collector area and recombine with the holes of the PN here (close to the collector).

In order to maintain balance, under the action of the positive electric field, the electrons in the collector area The electrons accelerate the movement of the outer collector, while the holes move at the pn junction. This process is similar to an avalanche process.

The electrons from the collector return to the emitter via the power supply, this is how a transistor works. When the transistor is working, both pn junctions will induce charges. When the switch tube is in the on state, the transistor is in a saturated state. If the transistor is turned off at this time, the charges induced by the pn junction will return to the equilibrium state. This process takes time. The MOS transistor works differently and does not have this recovery time, so it can be used as a high-speed switching tube.

(1) Field effect transistors are voltage control components, while transistors are current control components. When only a small amount of current is allowed to be taken from the signal source, a field effect transistor should be used; when the signal voltage is low and a large amount of current is allowed to be taken from the signal source, a transistor should be used.

(2) Field effect transistors use majority carriers to conduct electricity, so they are called unipolar devices, while transistors have both majority carriers and minority carriers to conduct electricity. It is called a bipolar device.

(3) The source and drain of some field effect transistors can be used interchangeably, and the gate voltage can be positive or negative, which is more flexible than transistors.

(4) Field effect transistors can work under very low current and very low voltage conditions, and its manufacturing process can easily integrate many field effect transistors on a silicon wafer. Therefore, field effect transistors are widely used in large-scale integrated circuits. has been widely used.

(5) Field effect transistors have the advantages of high input impedance and low noise, and are therefore widely used in various electronic devices. In particular, using field effect tubes as the input stage of the entire electronic device can achieve performance that is difficult to achieve with ordinary transistors.

(6) Field effect transistors are divided into two categories: junction type and insulated gate type, and their control principles are the same.

Read more: What is the difference between a transistor and a MOSFETBest seller SMT Machine :Qihe smt line products

-

TVM925 SMT pick and place machine 4 head 38 feeders slots assembly of electronic components

-

Q10 SMT Automatic pick and place machine 10 Heads 100 Slots High Precision and High Efficiency SMT/LED Assembly

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/