Compared with non-inverting and inverting operational amplifier circuits composed of resistors and operational circuits, ordinary people often find it more difficult to understand and master the principle of an integrating amplifier composed of capacitors and operational amplifiers. Recently, because a friend repeatedly discussed the principle of this circuit with me, I became a little cruel and wanted to explore this circuit.Today qihe smt pick and place machine sharing principles of Integrated Circuits Three Evolutions of Amplifiers and Capacitors .

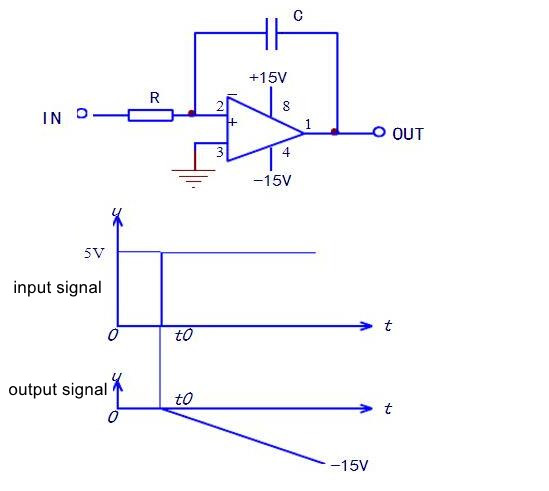

Replace the feedback resistor in the inverting amplifier with a capacitor to form an integrating amplifier circuit as shown in Figure 1. For resistors, they seem to be relatively real things, and the circuit output status can be seen at a glance. For capacitors, due to the uncertainty of charge and discharge, the capacitor is a relatively “virtual” object, and its circuit output status is a bit difficult to figure out.

The composition of the integrating circuit and the signal waveform diagram

To understand its output state, you must first understand the temperament of the capacitor. The basic function of a capacitor is to charge and discharge, and it is an energy storage component. It is sensitive to changing voltage (responses strongly), insensitive to DC (even indifferent), and has the characteristics of communicating AC and blocking DC. For those who view everything in the world as resistive characteristics, they can also think of capacitors as changing resistors, thus solving the mystery of the output of the integrating circuit.

According to the law of conservation of energy, energy cannot be generated without reason, nor can it disappear without reason. This leads to the theorem that the voltage across the capacitor cannot change suddenly. At the moment of charging, no charge is accumulated between the two plates of the capacitor, and the voltage at both ends can be maintained at the original state of zero. However, the charging current at this moment is the maximum, which can be equivalent to a very small resistance or even a wire.

If the capacitor is short-circuited at the moment of charging, it is not a bad idea. For example, in the main circuit of the frequency converter, current-limiting charging measures are required for the loop capacitor. This is exactly the reason; during the charging of the capacitor, as time goes by, the charging voltage gradually increases, and The charging current gradually decreases, and it can also be considered that the equivalent resistance of the capacitor changes from minimum to large at this time; after the capacitor is fully charged, the voltage at both ends is the highest, but the charging current is basically zero. At this time, the capacitor is equivalent to the maximum resistance. For direct current, it can even be equivalent to an open circuit, infinite resistance.

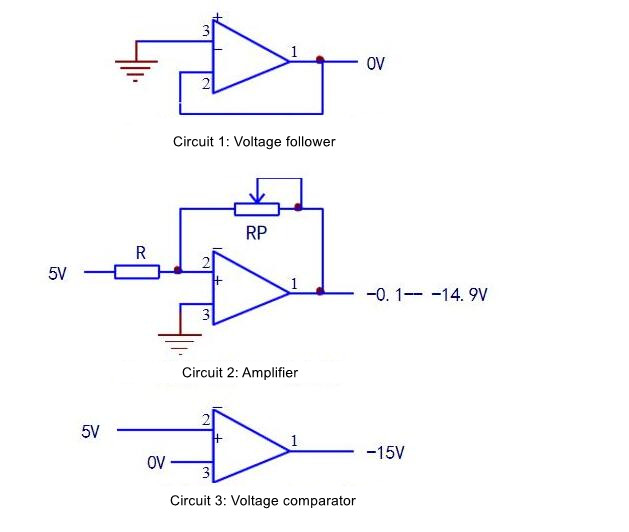

To summarize the above, during the charging process of the capacitor, there are three states: equivalent to the minimum resistance or wire, equivalent to the resistance from small to large, equivalent to the maximum resistance or open circuit. It is this changing characteristic of the capacitance that can transform the integrating amplifier circuit into the three identities shown in Figure 2.

Circuit 1. Voltage follower. At the t0 (forward transition) moment of the input signal, the capacitor charging current is the largest and the equivalent resistance is the smallest (or regarded as a wire). The circuit immediately transforms into a voltage follower circuit. From the virtual ground characteristics of the circuit, it can be seen that the output is still is 0V.

Circuit 2, inverting amplifier. During the flat-top period after the t0 moment of the input signal, the capacitor is in a relatively gentle charging process, and its equivalent RP goes through three stages: less than R, equal to R, and greater than R. Therefore, during the amplification process, under the action of the amplification characteristics, In fact, it has gone through three small processes: reverse phase attenuation, reverse phase, and reverse phase amplification. Whether it is attenuation, inversion or inversion amplification, it shows that at this stage, the integrating circuit actually plays the role of a linear amplifier.

Circuit 3. In the second half of the flat period of the input signal, the charging process of the capacitor has ended, the charging current is zero, the capacitor is equivalent to an open circuit, the integrating amplifier amplifies from the closed-loop to the open-loop comparison state, and the circuit then transforms into a voltage comparator. . The output value at this time is the negative supply value.

They say people can change their faces, but in fact circuits can also change their faces. Under capacitor control, the amplifier instantly changes into three identities. If you can see through these three identities of the integrating amplifier, the “true identity” of the integrating amplifier will be impossible to hide. Amplifiers are actually playing around in the circle of “amplification is inseparable from comparison, and comparison is inseparable from amplification.” I will leave this for later.

Read more: Principles of Integrated Circuits Three Evolutions of Amplifiers and CapacitorsBest seller SMT Machine :Qihe smt line products

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

-

QM61 SMT pick and place machine 6heads 63slots Fully Automatic Pick&place machine SMT Assembly chip mounter

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other smt pick and place products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series Q4,TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one smt pick and place device type.

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.smt pick and place

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, smt pick and place assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/