With the continuous development of the global economy, the environmental pollution caused by waste discharged by industrial equipment has become increasingly serious. It has become urgent to vigorously develop new energy-saving technologies and actively develop new power sources to reduce the dependence of industrial equipment on conventional fossil fuels. Using lithium-ion batteries as power energy devices for industrial equipment can solve this problem well.Today qihe smt pick and place machine sharing Battery Control Unit Reference Design .

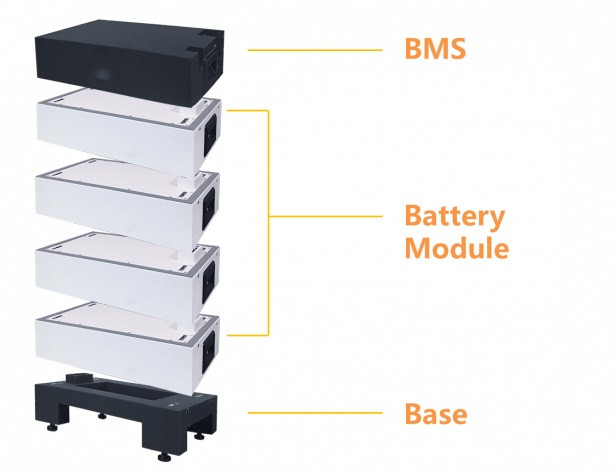

As a key component in the lithium battery power system, the battery management system (BMS) is the connection between the battery and the entire power system. The battery management system mainly determines the current working status of the battery by monitoring battery parameters (voltage, current, temperature, etc.) in real time. If there is an imbalance, the entire lithium battery pack is returned to the basic equilibrium state through the balance control unit.

At present, there are still some technical bottlenecks that need to be overcome in the application of power battery management systems on equipment. How to solve the problems that arise in the power lithium battery system is the main content of the battery management system designed in this article.

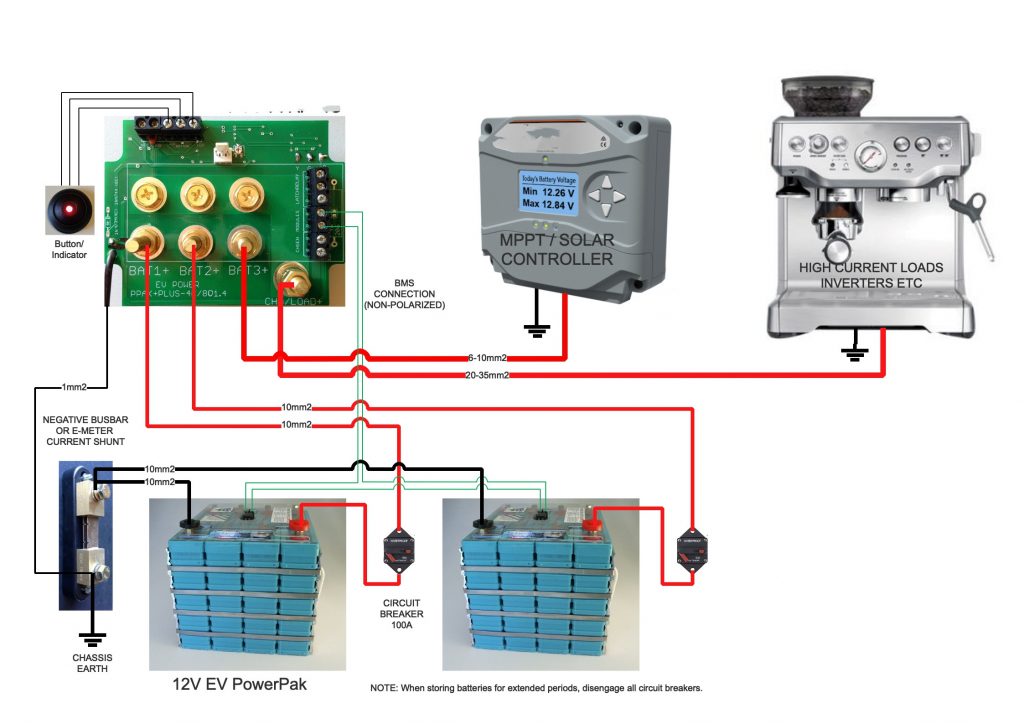

The battery balancing management system explained in this article mainly serves various industrial equipment powered by lithium batteries. The realization of each function of the lithium battery management system requires a complete hardware system to support it. Since a general lithium battery power system requires a large number of batteries, the versatility of the acquisition system must be taken into consideration in the design of the lithium battery management system; due to the complexity of the actual application site environment, the reliability and stability of BMS communication must be ensured

Field control unit module

The main function of the on-site control unit module is to obtain the voltage and temperature signals of the battery in the battery system through the data acquisition chip, process the obtained data through the controller, and then obtain the working status of the entire battery system and the estimated value of the host computer through algorithm processing. The remaining capacity of the battery system, if the battery energy is unbalanced, the on-site controller will start the corresponding balancing control unit circuit to achieve consistent energy balance of the entire battery pack, and provide the battery working status through the human-computer interaction interface in real time to users. If the battery fails, the user will be informed promptly and corresponding protective actions will be taken . Since this system requires communication with the lower computer and needs to be connected to peripherals such as a display screen, the on-site controller needs to have rich peripheral interfaces.

Data acquisition module

The underlying system is a battery data acquisition chip, and its functions mainly include related conditioning and acquisition of battery signals. The accurate collection of these signal data is particularly important for battery energy balance, and the formulation of battery storage energy usage strategies is crucial. The underlying data acquisition chip contains two acquisition modules: cell voltage acquisition module and battery cell temperature acquisition module . A data acquisition board collects the voltage of 3 battery cells and the temperature of 6 battery cells. Smt pick and place

Balanced control unit module

The main function of the balance control module is to transfer the data processed by the ATA6870 chip to the ATmega32HVB main controller to make balance control decisions based on the corresponding balance control algorithm, transfer the energy from the high-voltage battery cells and temporarily store it in the corresponding energy storage in the inductor, and then the energy is transferred to the adjacent battery cells through the energy storage inductor. This two-way balancing method with less energy consumption increases the overall capacity of the lithium battery pack and also slows down the deterioration of the lithium battery cells. (SoH)

Battery management chips are in the power management segment. The main product forms include battery metering (electricity There are three major categories of chips: meter),attery safety, and charging management. Battery management chip belongs to power management

Breaking down the track, the battery metering chip is used to determine the state of charge (SoC) and health of the battery.

(SoH) to estimate the battery state of charge; the battery safety chip is mainly used for battery status monitoring Smt pick and place

Control and balance the battery cells to avoid overcharge, over-discharge, over-current, short circuit and other faults; charging

Management chips are used to complete voltage conversion, regulation, battery charging management and overvoltage and overcurrent protection.

protection functions.

Consumer electronics market: The product competitiveness of domestic chips continues to improve, and the market share increases rapidly.

n the field of consumer electronics, mobile phones, laptops, smart wearables (headphones, watches), electrical engineering

Tools (robots, vacuum cleaners), etc. all require battery management chips. According to statistics from IDC and other statistics,

the sales (units/units) of mobile phones, PCs, PADs, watches, headphones, etc. will be 1.3 billion and 1.3 billion respectively.

270 million, 170 million, 130 million, 310 million. Among them, battery safety is a must for all types of electronic equipment.

chip. With the popularization of technologies such as fast charging, 5G, and large-capacity batteries, mobile phones, laptops,

PADs, high-end watches and headphones have higher and more urgent demands on battery metering chips.Smt pick and place

Best seller SMT Machine :Qihe smt line products

-

Q6 SMT pick and place machine 6heads 50slots With PCB Rail Servo Pick&Place Machine

-

Q4 SMT pick and place machine 4heads 50slots With PCB Rail Servo Pick&Place Machine

-

TVM802B Plus SMT pick and place machine 2heads 58slots desktop pick&place deluxe edition

-

QM10 SMT pick and place machine 10heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802BX SMT pick and place machine 2heads 46slots desktop pnp mounter deluxe edition

-

QL41 SMT pick and place machine 4heads 8slots LED for 1.2meters led strip pick&place machine

-

Q8 SMT pick and place machine 8heads 80slots Fully Automatic Chip mounter SMT Assembly

-

TVM802AX SMT pick and place machine 2heads 29slots desktop deluxe edition SMT Pick&Place Machine

-

QM61 SMT pick and place machine 6heads 63slots Fully Automatic Pick&place machine SMT Assembly chip mounter

What is SMT in engineering?

Surface mount technology is a part of the electronic assembly that deals with the mounting of electronic components to the surface of a PCB. Electronic components mounted this way are called surface-mounted devices (SMD). SMT was developed to minimize manufacturing costs while making efficient use of board space.Qihe SMT company develops and produces all kinds of SMT equipment suitable for world wide market, including pnp machine,reflow oven,stencil printer,pcb handling machines,and other products.

Small desktop pick and place machine TVM802A,TVM802B,TVM802AX,TVM802BX series suitable for beginners, for hobbiest or low vol usag.

Advanced level 4-head LED strip placement QL41 led machines and with rail universal series TVM925S,TVM926S,pick and place

Fully automatic 6-10-head placement QM61,QM62,QM81,QM10,machines, which are suitable for high volume mass production in factories.

Know more about us https://www.qhsmt.com/about-qihe-smt-equipment/

Follow us on social media https://www.facebook.com/Qihesmt/

What is SMT in programming?

Offline Automated Programming vs Inline SMT Programming

Qihe pick and place machine can be programmed directly on the SMT equipment .

Or Coordinates can also be imported csv file through programming software.

Currently supported software such as protel,DXP,Altium Designer,Pads,Candes,proteus,DXP.

Inline SMT programming is a solution to consider for narrow segments of device programming requiring short programming times, with medium to high volume, for just one device type.Smt pick and place

WHAT IS SMT pick and place machine?

SMT (Surface Mounted Technology) is a comprehensive system engineering technology, which covers substrates, design, equipment, components, assembly processes, production accessories and management. When it comes to SMT pick and place machines, the automatic SMT production line requires automatic loading and unloading machine, automatic solder paste printing machine, placement machine, reflow soldering machine, AOI inspection equipment, conveyor,connecting table, etc. For these SMT assembly line equipment, Qihe SMT can offer you machines in prototype SMT line, small SMT production line, mass production SMT line at low SMT line cost. Contact us now if you are interested.pick and place.pick and place machines,smt machine price,smt machine supplier,suction nozzle,smt assembly,feeder,stock in eu,pcb printer,openpnp feeder,openpnp,pcb pick and place,smt nozzle,smt line,smt meaning,smt process,smt setup,pnp machine,pcb assembly,p&p machine,p&p,pick&place,pick&place machine,pnp,stencil printer,reflow oven,pick and place machine,SMT equipment,smd machine,smt machine,SMT pick and place machine,pick and place machine,.

WHAT IS SMT ASSEMBLY LINE?

With the development of technology, future electronic products will be lighter, smaller and thinner. Traditional assembly technology can no longer meet the requirements of high-precision and high-density assembly. A new type of PCB assembly technology-SMT (Surface Mount Technology) has emerged. SMT Assembly is the use of automated machines to assemble electronic components on the surface of the circuit board. Its density, high speed, standardization and other characteristics occupies an absolute advantage in the field of circuit assembly technology. In addition, SMT assembly has a wide range of uses.

https://www.qhsmt.com/fully-automatic-smt-pick-and-place-machine-line/